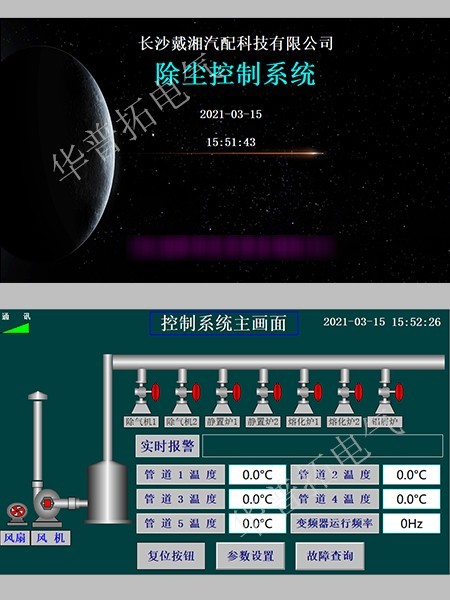

Programming screen for touch screen of Langfang diesel power generation system control cabinet

Product Introduction

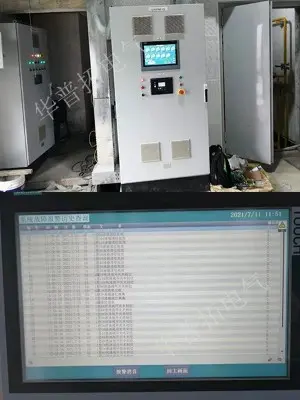

The Langfang diesel generator system electric control cabinet and touch screen PLC program programming screen design, as well as the on-site electric cabinet debugging, were all designed and completed by Kunshan Huaputuo Electric. Huaputuo Electric specializes in the production of PLC automatic control cabinets and is responsible for PLC software programming, control cabinet program screen layout and other services.

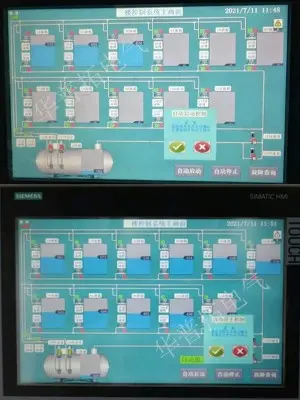

This system uses Siemens 1500 series redundant CPU. The software part is configured by wincc configuration software. The screen is output through the Siemens HMI screen. As shown in the figure, the control system diagram of the first and second floors, the interface can be touched to operate automatic start, automatic stop, system fault alarm history query, etc. It can be used as a reference for customers.

The left picture is a system diagram, which can intuitively show the liquid level status of each oil storage tank and the status indication of the underground oil tank. There are 22 oil storage tanks and 2 underground oil tanks on the first and second floors. Centralized automatic control. Convenient management.

Wincc configuration software can flexibly configure the hardware and software according to different process application objects, and call various monitoring and alarm screens required by basic graphics. PLC program system can improve the intelligence of automation equipment, reduce dependence on manual labor and reduce costs. PLC automation system helps enterprises improve efficiency.

Huapujie Electric provides non-standard customized automation control systems for enterprises, and cooperates with users to complete the automation control operation of equipment and on-site debugging. Welcome to call for information.

Company Strength

Innovative design capabilities

Gather more than 10 experienced technical engineers with the ability of power distribution and automatic control design and software programming development;

The two powerful forces joined forces to create Chen Yixin, which uses high intelligence to make the product structure and wiring more scientific, and the wiring inside the cabinet is reasonable and beautiful, showing the beauty of craftsmanship.

Production customization capabilities

With more than 10 years of experience in the production of low-voltage electrical equipment, we can customize exclusive automation control solutions according to customer needs;

We strictly implement the ISO9001 quality management system, all products have passed 3C certification, and the production progress nodes are tracked in time to ensure on-time delivery.

Quality and price guarantee system

Huapujie Electric has long-term cooperation with Siemens, Schneider, ABB, Rockwell and other brand component manufacturers, with genuine and high-quality configuration;

High-quality raw materials are purchased centrally, with lower costs, stable performance, and complete functions, and can be combined according to the actual control scale.

Technical collaboration support

Original technical support, collaborative product upgrade and optimization, establishment of a 7*24-hour rapid response mechanism, and full-time project engineers to guide operations at any time;

The project will be followed up by a dedicated project engineer from the early stage to the later stage to avoid information errors and the time required to familiarize yourself with the project again.

Intelligent Manufacturing / Industry 4.0

Intelligent Manufacturing / Industry 4.0 Motor Control Center MCC

Motor Control Center MCC Data Center

Data Center Environmental Industry

Environmental Industry Industrial Machinery

Industrial Machinery New Energy

New Energy Pharmaceutical Manufacturing

Pharmaceutical Manufacturing Petroleum & Chemical

Petroleum & Chemical Marine & Offshore & Ship

Marine & Offshore & Ship Food processing / agricultural production

Food processing / agricultural production