Pre treatment control system PLC electrical cabinet for electrophoretic coating line

Product Introduction

This electrical cabinet system is tailor - made for the spray coating industry, playing a pivotal role in the electrophoretic coating line. It mainly consists of a PLC electrical cabinet and a frequency converter starter cabinet in the pre - treatment control system.

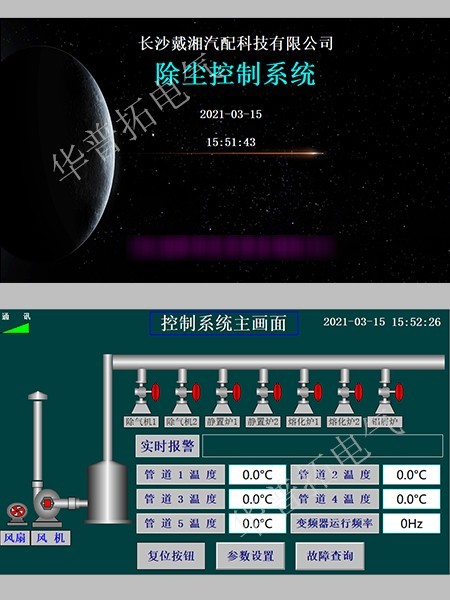

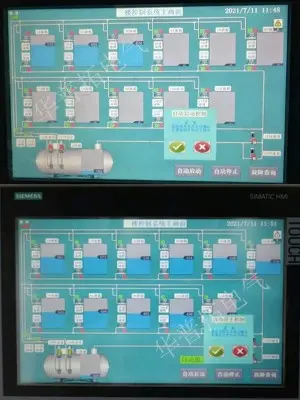

The main control cabinet is equipped with a Siemens 1500 series CPU6ES7511, paired with an ET200 PLC module. This configuration endows the system with high - speed data processing capabilities and stable operation performance, ensuring accurate and timely response to various control commands. The Siemens 12 - inch touch screen is utilized for programming and screen display output. Its user - friendly interface enables operators to easily set parameters and monitor equipment status, significantly enhancing operational efficiency. Huapu Tuo's professional engineers have embedded a customized process code into the electrical cabinet. This code allows for real - time and intuitive monitoring of pre - treatment processes such as spray degreasing and water washing. For example, during spray degreasing, the system can precisely control the spraying volume and pressure of the degreasing agent according to pre - set parameters, while for water washing, it can regulate the water flow rate and washing time, ensuring high - quality pre - treatment effects.

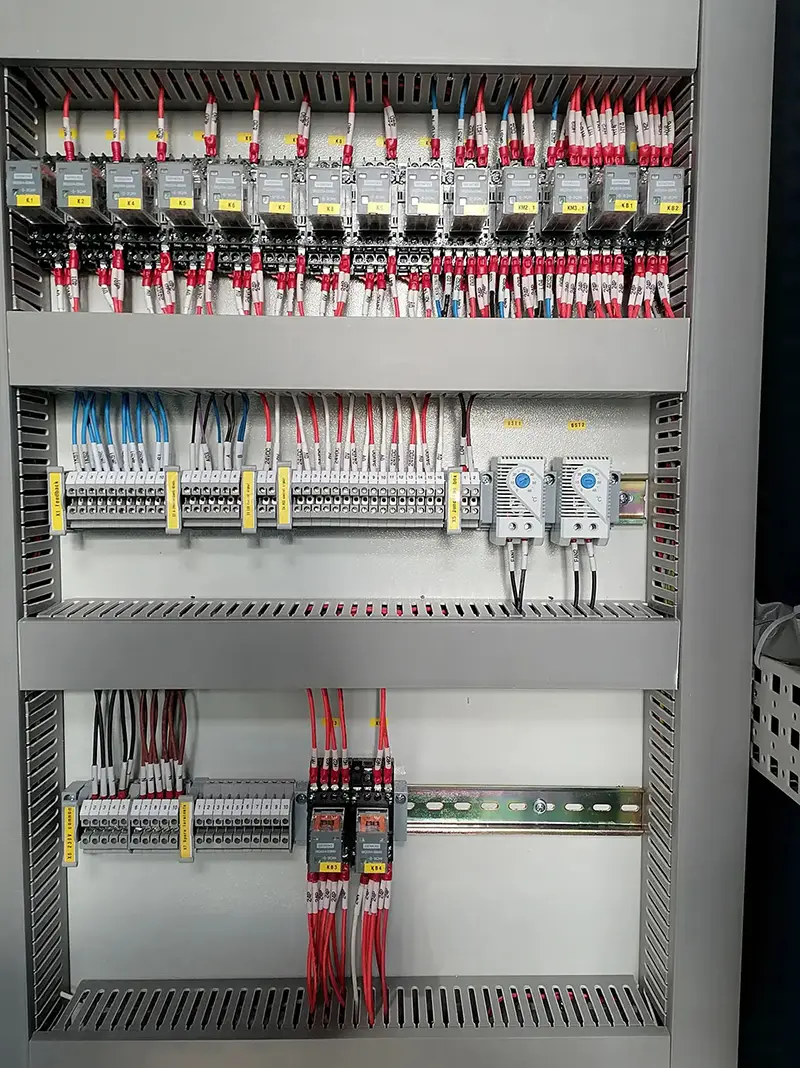

In total, this project encompasses 10 electrical cabinets. Six of them are dedicated to the pre - treatment and electrophoresis drying control system of the component electrophoresis coating line. These cabinets are responsible for the entire pre - treatment process, from the moment the conveyor chain brings in the components, through spray degreasing to remove oil and impurities on the surface, water washing to rinse away the remaining degreasing agent and dirt, and silane treatment to improve the adhesion of the coating. The other two electrical cabinets are for the powder drying control system of the component electrophoresis coating line, which is crucial for the final powder - coating curing process. All these cabinets feature front and rear double - door designs. This design not only facilitates equipment installation and debugging but also simplifies subsequent maintenance work, reducing maintenance time and improving equipment availability.

The components within the cabinets are sourced from top - tier brands in the industry, including Siemens, Schneider, and Omron, guaranteeing high - quality and reliable performance. The Huichuan frequency converter is selected as the starting component. Based on the actual power requirements of on - site motors, 12 frequency converters of different capacities, such as 45KW, 30KW, and 7.5KW, are carefully configured. This ensures that motors of various powers can start smoothly, reducing the impact of starting current on the power grid and enabling precise speed regulation to meet the diverse technological requirements during the production process.

The six front - end processing control system electrical cabinets are connected in parallel, which not only maintains the integrity of the control system but also optimizes the overall layout. Their appearance is sleek and the structure is rational, and they are arranged in strict accordance with the process flow. This orderly arrangement promotes seamless cooperation among different processes, realizing highly efficient mechanical automation production.

In terms of power supply, the pre - treatment control cabinet of the electrophoretic coating line requires a DC 24V power supply and a single - phase AC 220V power supply with a voltage range of (- 10%, + 15%) and a frequency of 50HZ. The protection level reaches IP41 or IP54, providing effective protection against dust and water splashing.

Regarding environmental conditions, the ambient temperature should be maintained between 0 ℃ and 55 ℃ to avoid direct sunlight, as excessive heat or cold can affect the performance and lifespan of electrical components. The relative humidity of the air should be less than 85% (without condensation) to prevent short - circuits and corrosion caused by moisture. The cabinets should be kept away from strong vibration sources, as vibrations with a frequency of 10 - 55HZ can loosen connections and damage components. Additionally, the working environment should be free of corrosive and flammable gases to ensure the safe and stable operation of the electrical cabinets.

Intelligent Manufacturing / Industry 4.0

Intelligent Manufacturing / Industry 4.0 Motor Control Center MCC

Motor Control Center MCC Data Center

Data Center Environmental Industry

Environmental Industry Industrial Machinery

Industrial Machinery New Energy

New Energy Pharmaceutical Manufacturing

Pharmaceutical Manufacturing Petroleum & Chemical

Petroleum & Chemical Marine & Offshore & Ship

Marine & Offshore & Ship Food processing / agricultural production

Food processing / agricultural production