Case Study of PLC Variable Frequency Control Cabinet for Jiangsu Youkang Ecological Mushroom Water Phase II Pure Water System

project introduction

Case Study of PLC Variable Frequency Control Cabinet for Jiangsu Youkang Ecological Mushroom Water Phase II Pure Water System

The PLC frequency conversion cabinet consists of two ABB frequency converters, one in use and one as backup. Meet the long-term operation requirements of the on-site pure water system. Schneider brand is selected for the air circuit breaker with molded case. PLC intelligent control is composed of Siemens expansion modules. The cabinet is equipped with Kunlun Tongtai brand monitors. You can visually see the output values and images.

Application Highlights

● PLC programmable intelligent control, relying on PLC expansion modules as the carrier. The process of automated control is achieved by editing and storing code programs through Wincc software.

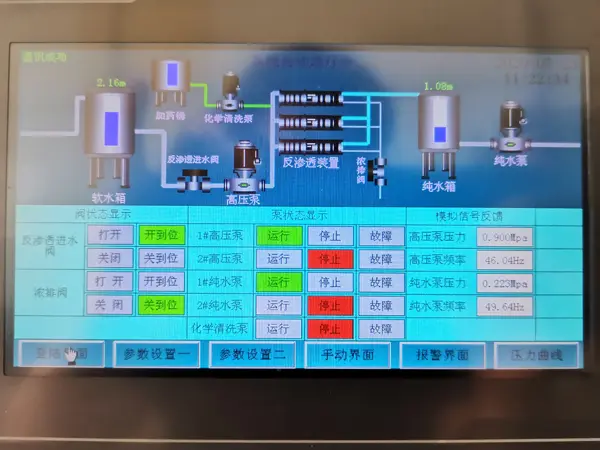

● As shown in the figure on the right, the program outputs a visual image through the touch screen. And present the entire process of pure water evolution through a visual overview. More understandable.

● Display the valve and pump status during the automatic operation of the pure water system. And provide feedback on simulated signals, including various pressure and frequency values.

● There are always upper and lower interface buttons at the bottom of the screen, which can be switched to view settings at any time. For example, login interface, parameter settings, monitoring interface, manual interface, alarm interface, and numerical pressure curve chart.

● It can be manually and automatically switched freely, suitable for use by operators at all levels on site.

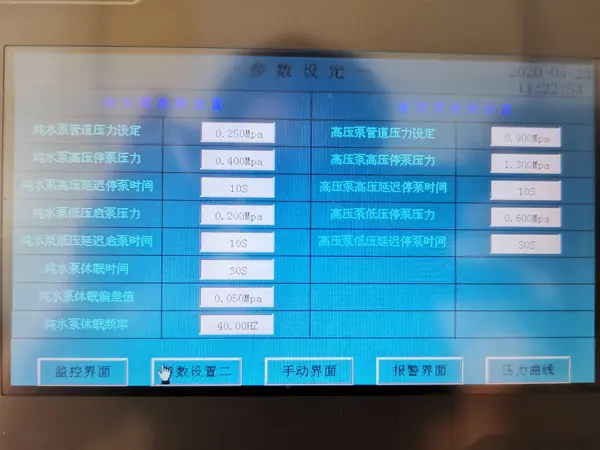

● Parameter setting is divided into two parts. Parameter setting one includes the pressure of the pure water pump pipeline, the delay time for high-pressure pump shutdown, and the sleep time and frequency. There are also various parameter settings for the high-pressure pump. Parameter setting two, liquid level settings for pure water tank and soft water tank.

● Flexible local/remote switching, convenient for on-site control. Improve efficiency and reduce costs.

Intelligent Manufacturing / Industry 4.0

Intelligent Manufacturing / Industry 4.0 Motor Control Center MCC

Motor Control Center MCC Data Center

Data Center Environmental Industry

Environmental Industry Industrial Machinery

Industrial Machinery New Energy

New Energy Pharmaceutical Manufacturing

Pharmaceutical Manufacturing Petroleum & Chemical

Petroleum & Chemical Marine & Offshore & Ship

Marine & Offshore & Ship Food processing / agricultural production

Food processing / agricultural production