In today's rapidly evolving industrial landscape, the selection of an appropriate Electric Box Cabinet has become increasingly crucial for businesses aiming to enhance operational efficiency and safety. According to a recent report by MarketsandMarkets, the global market for electrical enclosures, which includes electric box cabinets, is expected to grow significantly, reaching $7.12 billion by 2025, driven by the rising demand for energy-efficient solutions and stringent regulatory standards across various sectors. These cabinets play a pivotal role in protecting electrical components from environmental hazards, thereby reducing maintenance costs and downtime. Additionally, a well-chosen Electric Box Cabinet can contribute to system optimization, ensuring that the intricate network of electrical equipment operates seamlessly. Understanding the different types of electric box cabinets and their specific applications is essential for businesses to meet both operational needs and compliance requirements effectively.

When selecting the ideal electric box cabinet for your business, it is crucial to first assess your specific needs. Every business has unique requirements based on the industry, size, and type of equipment being used. For instance, a manufacturing plant may require robust cabinets that can withstand environmental factors such as dust and moisture, while an office setting might prioritize aesthetics and space efficiency. Understanding these factors will help narrow down the options significantly.

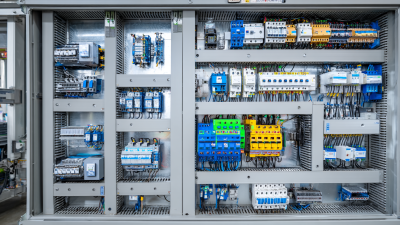

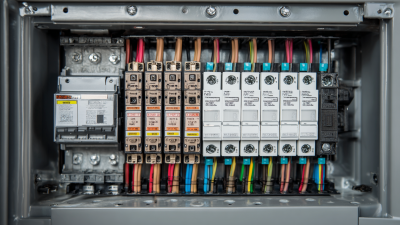

Another important consideration is the capacity and functionality of the cabinet. Evaluate how many electrical components you need to store and whether you require additional features, such as surge protection, ventilation, or security locks. Make sure the chosen cabinet can accommodate your current equipment and allow space for future expansions. By thoroughly understanding your business needs, you can choose an electric box cabinet that not only meets operational requirements but also enhances safety and efficiency.

When selecting the perfect electric box cabinet for your business needs, several key features should be prioritized. First and foremost is the material and durability of the cabinet. With the global electrical enclosure market projected to reach USD 87.4 billion by 2035, the importance of high-quality materials that can withstand varying environmental conditions cannot be overstated. Look for enclosures made from robust materials, such as stainless steel or high-grade plastic, ensuring they provide adequate protection against moisture, dust, and other contaminants.

Another crucial aspect to consider is the size and capacity of the cabinet. A report indicating the electrical enclosure market size was USD 52.17 billion in 2024 highlights the growing demand for efficient storage solutions. Depending on your equipment and operational requirements, it’s essential to choose a cabinet that offers enough space for your electrical components while also allowing for future expansion. Lastly, consider the ease of installation and access. Cabinets that provide user-friendly design features, such as removable doors and adjustable mounting options, can significantly enhance your operational efficiency and safety.

When choosing an electric box cabinet for your business, one crucial aspect to consider is the material—metal or plastic. Each option has its own set of advantages and disadvantages, particularly in terms of durability, cost, and environmental impact.

Metal cabinets are typically known for their strength and durability, making them ideal for harsh environments. They provide a high level of protection against external factors, such as fire and moisture, and can generally withstand more significant wear and tear. However, it's essential to note the environmental implications of metal, including its heavier carbon footprint during production compared to some plastic alternatives.

On the other hand, plastic cabinets can offer considerable benefits, particularly in terms of weight and resistance to corrosion. Recent studies suggest that plastic materials, including those that are recycled, can have a lesser environmental impact in terms of greenhouse gas emissions compared to metal. When selecting plastic products, however, ensure they meet safety standards, especially if they will come into contact with food or skin.

**Tips:** When considering plastic, check if they are made from recycled materials, as this can enhance sustainability. Also, conduct thorough research on the physical and chemical properties of the plastic to mitigate any risks. For metal cabinets, inspecting the finishing and coatings will ensure long-lasting protection against rust and corrosion.

When selecting an electric box cabinet for your business, effective space optimization should be a top priority. First, assess the layout of your workspace. Consider the flow of movement and accessibility around the cabinet location. It’s crucial to ensure that the cabinet is positioned where it won’t obstruct workflow or emergency exits. Aim for areas that maximize access but also can accommodate necessary clearances for maintenance and operation, minimizing disruptions to your daily activities.

Additionally, think about vertical space utilization. If floor space is limited, opt for taller cabinets that make use of vertical dimensions without compromising accessibility. Wall-mounted cabinets can also be a great solution in tight spaces, freeing up valuable floor area while keeping important electrical systems within reach. Incorporate organizational tools within the cabinet, such as shelving or compartments, to further enhance efficiency and accessibility. Prioritizing these space optimization techniques will help streamline operations and create a more organized business environment.

When budgeting for your electric box cabinet purchase and maintenance, it's essential to consider both initial costs and ongoing expenses. According to a report by the National Electrical Manufacturers Association (NEMA), the average cost of a mid-range electric box cabinet can range from $500 to $1,500, depending on size and material. However, businesses must not overlook additional expenses such as installation, upgrades, and routine maintenance, which can constitute up to 20% of the initial investment over the lifespan of the equipment.

Maintenance costs typically arise from ensuring the cabinet meets industry standards and operates efficiently. A survey conducted by the Electrical Safety Foundation International (ESFI) highlighted that businesses spend approximately 3-5% of their equipment's value annually on preventive maintenance. Investing in high-quality cabinets can reduce these costs, as they tend to have a longer lifespan and require less frequent repairs. Therefore, a thorough understanding of both the initial purchase price and the projected maintenance costs is crucial for making a financially sound decision tailored to your business needs.

| Feature | Description | Estimated Cost ($) | Maintenance Frequency | Lifespan (Years) |

|---|---|---|---|---|

| Size | Available in various sizes to fit your space requirements. | 300 - 800 | Annually | 10-15 |

| Material | Durable materials like steel or fiberglass for durability. | 400 - 900 | Every 6 Months | 15-20 |

| Customization | Options for customizing layout and design based on your needs. | 100 - 300 (additional) | As Needed | 10-25 |

| Safety Features | Includes lockable doors, ventilation, and thermal insulation. | 250 - 700 | Quarterly | 10-20 |

| Energy Efficiency | Designed to minimize energy consumption and reduce costs. | 200 - 500 | Annually | 15-30 |