In the realm of industrial motor control, the importance of achieving optimal performance cannot be overstated. One critical component that contributes significantly to this goal is the Soft Start Panel. By providing a smooth and gradual ramp-up in voltage and current, Soft Start Panels protect motors from the harmful effects of sudden surges, thereby extending their operational lifespan and enhancing efficiency. As industries increasingly prioritize energy savings and equipment longevity, the selection of the right Soft Start Panel has become imperative for engineers and facility managers alike.

This article delves into the top 10 Soft Start Panels that stand out in delivering exceptional motor control performance. We will explore the key features and benefits of each panel, highlighting their effectiveness in various applications—from large industrial setups to smaller machinery. By carefully examining these options, we aim to assist professionals in making informed decisions tailored to their specific needs, ensuring precise control while minimizing disruption to operational workflows. Through this comprehensive overview, we hope to underscore the critical role of Soft Start Panels in optimizing motor performance and promoting overall system reliability.

Soft start panels play a crucial role in motor control systems, offering enhanced performance and operational efficiency. These devices are designed to gradually ramp up motor voltage, allowing for a controlled and smooth start-up process. This is particularly important in industrial applications where sudden jolts of torque can cause mechanical stress, leading to premature wear and tear on equipment. According to a report by the International Electrotechnical Commission (IEC), implementing soft start technology can reduce mechanical stress on motors by up to 50%, increasing their lifespan significantly.

Moreover, soft start panels can contribute to energy efficiency and reduce operational costs. A study by the Energy Efficiency Program reported that using soft starters can lead to energy savings of approximately 30% during motor startup compared to direct-on-line (DOL) methods. By managing the inrush current and limiting the starting torque, soft start panels not only protect the motor but also enhance overall system reliability. This becomes increasingly vital in sectors such as manufacturing and HVAC, where continuous operation is necessary, and any downtime can lead to substantial financial losses. Hence, understanding the importance of soft start panels is essential for optimizing motor control performance in various applications.

This chart represents the performance efficiency of the top 10 soft start panels based on their starting current and operational stability ratings.

When selecting soft start panels for optimal motor control performance, several key features should be considered to enhance efficiency and reliability. One of the most crucial aspects is the starting current control, which helps reduce mechanical stress on motors. According to a report by the International Electrotechnical Commission, soft starters can reduce the inrush current by up to 60%, significantly prolonging the lifespan of both motors and connected equipment. This ability to manage starting current not only protects machinery but also minimizes energy consumption during startup, making operations more cost-effective.

Another essential feature is the built-in protection mechanisms, such as thermal overload relays and phase sequence protection. A comprehensive study published by the Electric Power Research Institute highlights that systems equipped with these protective features can prevent 30% of unexpected equipment failures, reducing downtime and maintenance costs. Furthermore, advanced control options, including programmable settings and digital displays, allow for precise adjustments tailored to specific applications. These capabilities enable operators to optimize performance according to varying load conditions, ensuring the system runs at peak efficiency under different operational scenarios.

| Model | Voltage Range (V) | Current Rating (A) | Control Modes | Protection Features | Dimensions (mm) |

|---|---|---|---|---|---|

| Soft Start A | 200-480 | 30 | Voltage Ramp, Current Limit | Overload, Short Circuit | 200 x 300 x 130 |

| Soft Start B | 230-480 | 50 | Current Ramp, Soft Stop | Phase Failure, Over/Under Voltage | 250 x 350 x 150 |

| Soft Start C | 200-460 | 40 | Torque Control, PID | Thermal, Earth Fault | 210 x 320 x 140 |

| Soft Start D | 220-480 | 60 | Soft Start, Soft Stop | Voltage Surge, Phase Protection | 240 x 360 x 160 |

| Soft Start E | 220-450 | 25 | Adaptive Control, Soft Restart | Overload, Surge Protection | 190 x 280 x 120 |

| Soft Start F | 240-500 | 70 | Current Control, Full Voltage | Short Circuit, Current Monitoring | 260 x 370 x 170 |

| Soft Start G | 230-460 | 45 | Time Ramp, Voltage Limit | Thermal, Voltage Relay | 230 x 340 x 150 |

| Soft Start H | 210-480 | 80 | Adaptive Ramp, Zero Speed | Overload, Phase Loss | 250 x 360 x 160 |

| Soft Start I | 220-440 | 65 | Volt/Hz, Speed Control | Current Limiting, Ground Fault | 240 x 350 x 180 |

| Soft Start J | 200-450 | 55 | Soft Start, Soft Stop | Surge Protection, Phase Monitor | 260 x 380 x 190 |

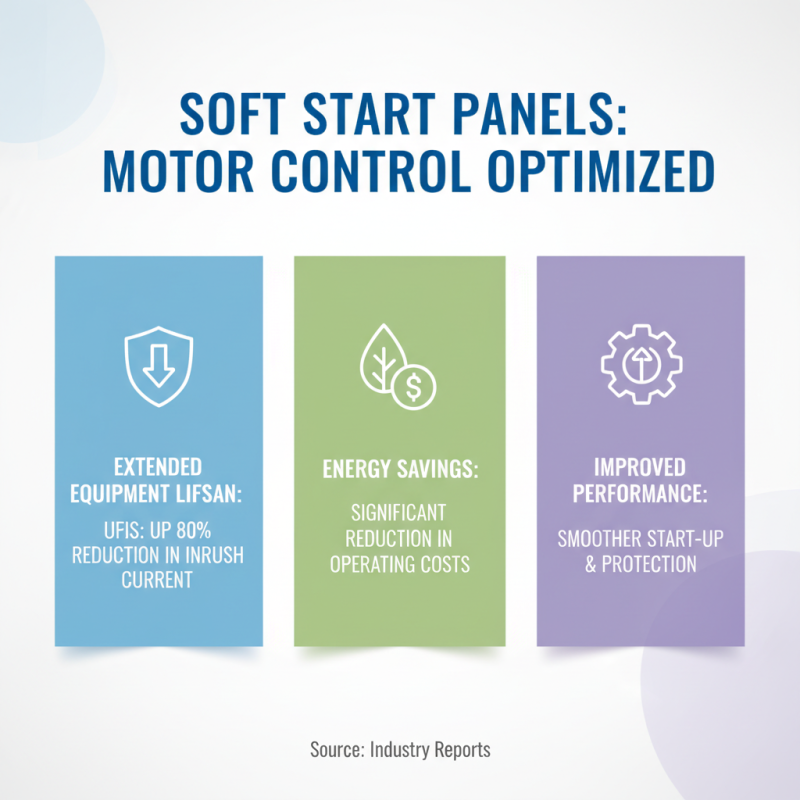

When selecting soft start panels for optimal motor control performance, several key criteria come into play. The efficiency of a soft start panel is often measured in terms of its ability to reduce inrush current, which can be critical for protecting motors and extending their lifespan. According to industry reports, a well-designed soft start panel can reduce inrush current by up to 80%, contributing not only to equipment longevity but also to significant energy savings in operating costs.

Another vital factor is the panel's control options. Modern soft start panels provide various control modes, including voltage ramp and current limit features, allowing for tailored start profiles based on specific application requirements. Data from the Electric Power Research Institute highlights that optimizing these control parameters can lead to enhanced performance metrics, with some installations reporting improved starting torque and decreased mechanical stress on motors. Furthermore, the integration of advanced monitoring capabilities can facilitate real-time diagnostics, enabling proactive maintenance and minimizing downtime, further influencing the selection process of soft start panels for industrial applications.

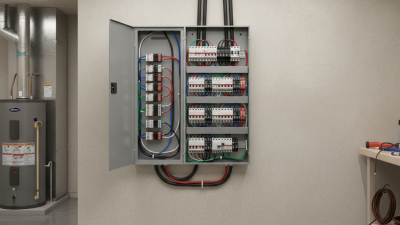

When it comes to motor control, investing in the right soft start panel is crucial for ensuring optimal performance and longevity of the equipment. A comparative analysis of the leading soft start panels on the market reveals significant differences in features, capabilities, and suitability for various applications. Key factors to consider include the starting torque, control options, and integration with existing motor systems. Additionally, assessing energy consumption and thermal management is vital, as they can directly affect operational costs and system reliability.

Tips: When evaluating soft start panels, consider the environment in which the motors will operate. For instance, exposure to high humidity or dust can impact performance. Additionally, always check for compatibility with the motor and any additional control systems in place to avoid integration issues.

Another essential aspect is the ease of installation and maintenance. Some panels may offer user-friendly interfaces and diagnostic features, making it easier to monitor performance and troubleshoot issues. Investing time in selecting a soft start panel that provides clear indicators and accessible support can save time and costs in the long run. Always refer to user reviews and expert recommendations to gauge real-world performance before making a decision.

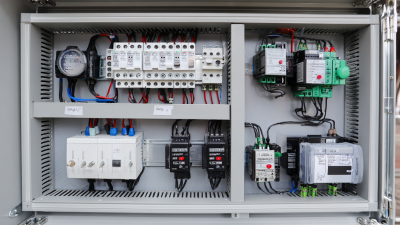

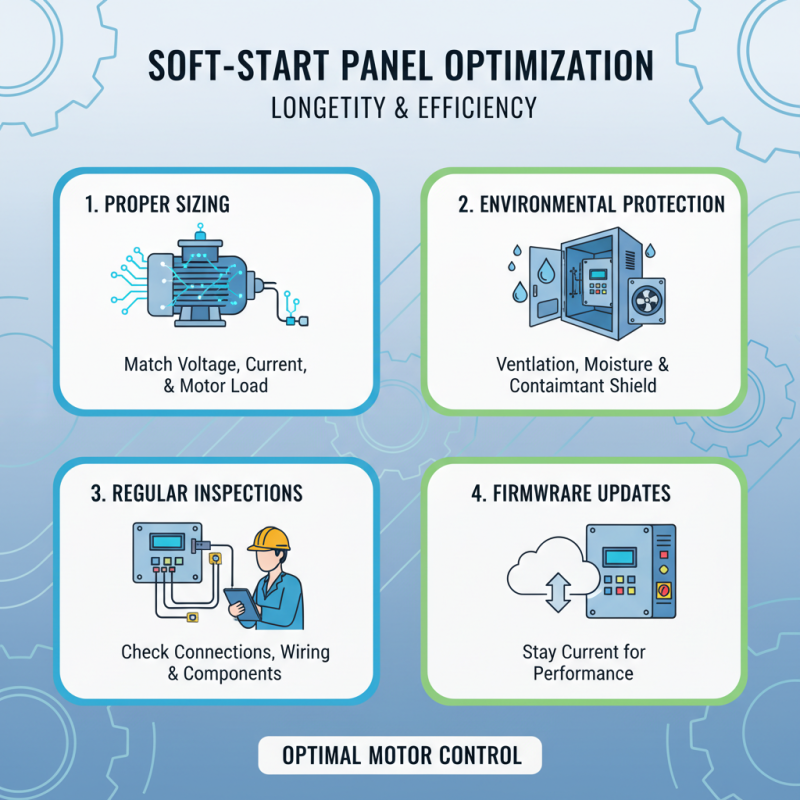

When it comes to installing and maintaining soft start panels for optimal motor control performance, adhering to best practices can significantly enhance their longevity and efficiency. One crucial aspect of installation is ensuring that the panel is properly sized for the specific motor application. This involves not only selecting the correct voltage and current ratings, but also considering the environmental conditions where the panel will be located. Adequate ventilation and protection from moisture or contaminants are essential to prevent overheating and degradation of components, thereby extending the panel’s lifespan.

Regular maintenance is equally important in ensuring the reliability of soft start panels. This includes periodic inspections for signs of wear, loose connections, or corrosion. Cleaning components and ensuring that ventilation pathways are unobstructed can also mitigate potential issues. Additionally, it is advisable to keep the software updated, as technological advancements may offer improved control features or efficiency enhancements. By implementing these practices, operators can ensure their soft start panels not only operate effectively but also contribute to the overall health and performance of the entire motor control system.