In the world of industrial automation, the "Plc Hmi Control Panel" stands out as a crucial tool. Experts emphasize the significance of its features. John Smith, a renowned automation specialist, once stated, "Understanding the capabilities of a Plc Hmi Control Panel can transform operational efficiency." His insight highlights the need to explore its essential functions.

The Plc Hmi Control Panel integrates human-machine interaction seamlessly, enabling users to monitor and control machinery effectively. Its user-friendly interface is designed for quick learning. However, while most operators appreciate the simplicity, some still struggle to utilize advanced features. This gap calls for more comprehensive training and awareness.

Moreover, the adaptability of these control panels makes them invaluable in various industries. They can interface with multiple devices and systems, ensuring smooth communication. Yet, potential challenges, such as connectivity issues or software bugs, remind us that no system is perfect. Continuous improvement is vital as the landscape of automation evolves, pushing us to re-evaluate how we use the Plc Hmi Control Panel effectively.

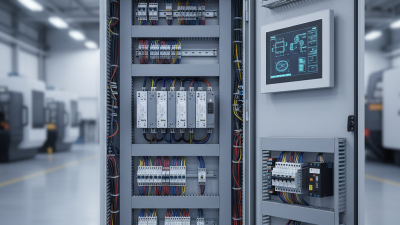

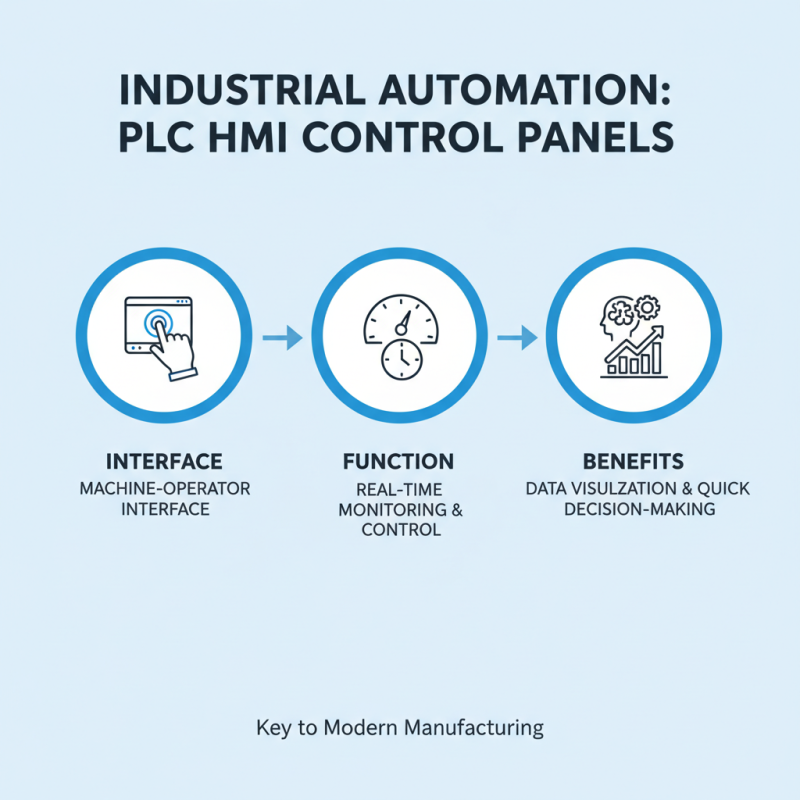

PLC HMI control panels play a crucial role in industrial automation. They serve as the interface between machines and operators. Their primary function is to facilitate real-time monitoring and control. Operators can visualize machine status, making it easy to understand performance metrics. A well-designed interface presents data clearly. This helps in quick decision-making.

Another key functionality is alarm management. Effective alert systems notify users of any irregularities. These alarms can indicate equipment failure, which ultimately reduces downtime. Additionally, PLC HMI systems often allow for customizable dashboards. This means operators can prioritize the most relevant information based on their tasks.

Despite these features, challenges remain. Many operators struggle with user interface complexity. Some panels can be overwhelming for new users. Continuous training is essential to ensure efficiency. Also, while functionality is vast, not all features may be utilized in every situation. Streamlining what is needed can help teams focus on critical operations. Balancing these aspects requires ongoing reflection and improvement.

User interface design is crucial for HMI control panels. An intuitive interface enhances usability and productivity. According to a study by the International Society of Automation, 70% of operators struggle with complex interfaces. This leads to mistakes and increases downtime.

Effective design elements include clarity and simplicity. Colors should be distinctive, guiding the operator’s attention to critical areas. Font sizes must be legible, ensuring that important data is easily read. Touch targets must also be large enough for quick interactions. Yet, some designers overlook the space needed for buttons and controls, leading to crowded screens.

HMI panels often suffer from inconsistent layouts. While standardization can improve user experience, many applications still lack uniform design. This inconsistency creates confusion and slows down response times. Regular user feedback is essential but often neglected. It can guide improvements and minimize errors in operational settings.

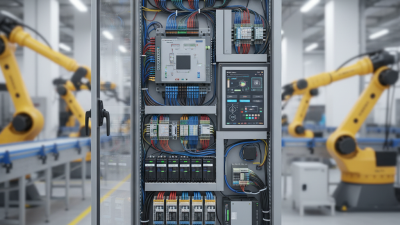

The integration of Programmable Logic Controllers (PLC) and Human-Machine Interfaces (HMI) is pivotal in modern automation systems. This combination enhances efficiency and productivity. A PLC processes data and executes control commands. An HMI provides a visual interface for operators. When these systems work together, they simplify complex operations. Operators gain real-time insights, enabling faster decisions.

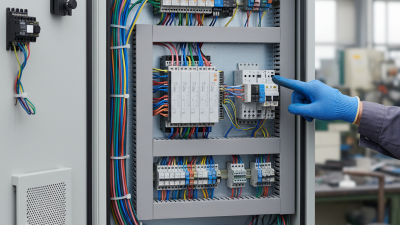

However, implementing this integration can be challenging. Miscommunication between the PLC and HMI can lead to errors. Proper configuration is essential. A poorly set up system may lead to delays or even shutdowns. Moreover, operators need adequate training to use HMIs effectively. Without this, the advantages of integration may be lost.

Visual feedback from the HMI allows operators to monitor processes closely. Charts and graphs present data clearly. This data can help identify trends over time. Yet, reliance on this data can sometimes obscure underlying issues. Operators must remain vigilant and not solely depend on visual aids. Balancing technology and human awareness is crucial for success in automation.

PLC HMI control panels play a vital role in various industries. They improve efficiency and enhance operational safety. You can find these panels in manufacturing plants, water treatment facilities, and automation systems. They provide real-time monitoring and control of processes. This integration allows operators to respond quickly to issues, minimizing downtime.

In manufacturing, these panels oversee machinery and production lines. They help in tracking performance metrics. In water treatment, PLC HMI controls the treatment process, ensuring compliance with safety standards. However, their design can sometimes be complex. Operators might need extensive training to maximize their potential.

The versatility of PLC HMI control panels makes them valuable. Yet, there's room for improvement. User interfaces can be made more intuitive. Feedback from operational staff is crucial. It can lead to better designs and functionality. Balancing complexity and usability is essential for optimal performance.

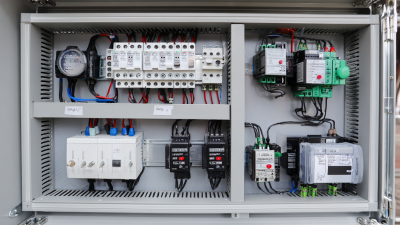

| Feature | Description | Common Applications |

|---|---|---|

| User-Friendly Interface | Intuitive graphical user interface for easy monitoring and control. | Manufacturing plants, assembly lines. |

| Real-Time Data Monitoring | Provides real-time data visualization and status updates. | Energy management, process automation. |

| Alarm Management | Watches for system errors and alerts users to potential issues. | Chemical processing, water treatment facilities. |

| Data Logging | Records and stores operational data for analysis and reporting. | Food and beverage manufacturing, HVAC systems. |

| Remote Access | Allows operators to monitor and control systems from remote locations. | Oil and gas industry, utilities management. |

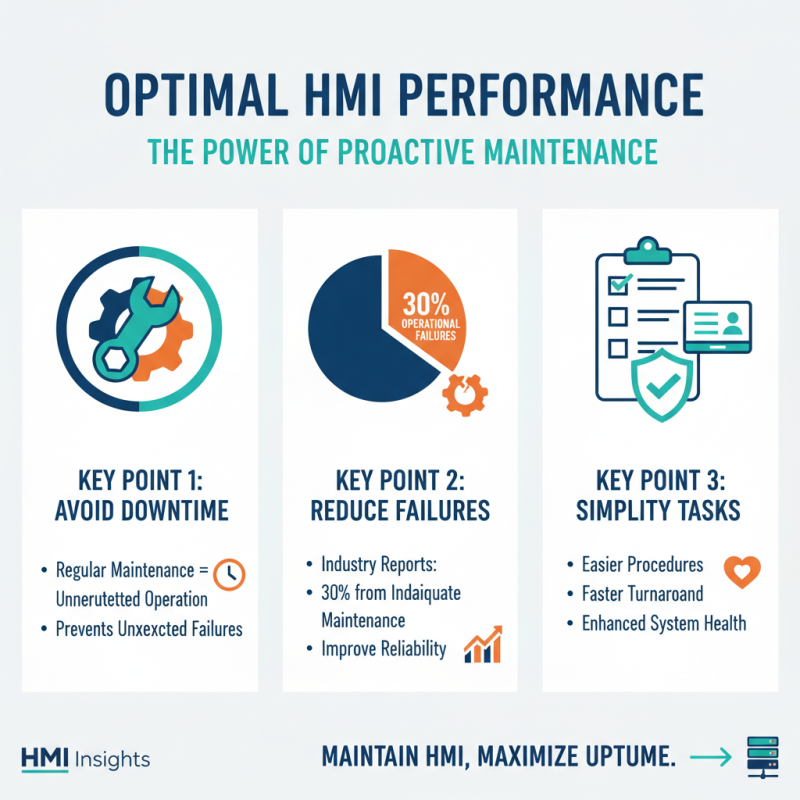

Maintaining HMI systems is crucial for optimal performance. Regular maintenance helps in avoiding unplanned downtime. According to industry reports, around 30% of operational failures stem from inadequate maintenance practices. Simplifying maintenance tasks can improve system reliability.

Routine inspections are vital. Check for software updates and system bugs regularly. Users should also monitor performance metrics. If response times lag, it may indicate underlying issues. A study showed that timely updates can enhance system efficiency by up to 25%. Addressing these factors early can save costs.

Documentation of each part’s performance is essential. Users often overlook this step. Tracking maintenance routines ensures no details slip through the cracks. However, it’s common to misplace records or forget to document. This can lead to serious gaps in maintenance history. Simple, organized logs can help mitigate these problems.