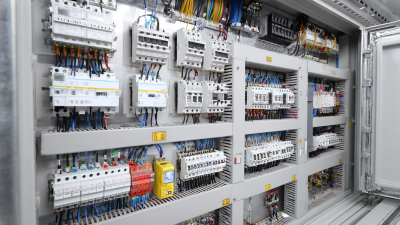

As the demand for efficient and sustainable electrical solutions continues to rise, the Pcc Panel industry is on the verge of groundbreaking innovations poised to transform the landscape by 2025. Industry expert Dr. Emily Johnson, a leading figure in power distribution technology, asserts, “The future of Pcc Panels lies in their ability to integrate advanced digital technologies, enhancing both performance and reliability.” This statement underscores the critical role that innovation plays in shaping the next generation of Pcc Panels.

In this dynamic context, organizations are exploring new designs, materials, and technologies to meet the evolving needs of industries across the board. From smart monitoring systems to eco-friendly materials, the upcoming innovations in Pcc Panels are set to revolutionize how we think about power management. As we delve deeper into the top ten Pcc Panel innovations to watch for in 2025, it becomes evident that these advancements will not only improve efficiency but also contribute significantly to sustainability goals.

The intersection of technology and utility in Pcc Panels heralds a new era for electrical systems. By incorporating cutting-edge features and sustainable practices, the industry is paving the way for a more efficient and resilient future. As we explore these innovations, it is crucial to recognize the potential impact they will have on various sectors and the overarching goal of achieving a smarter, greener grid.

The use of innovative materials in PCC (Precast Concrete) panels is set to revolutionize the construction industry by 2025. As the demand for durable and sustainable building solutions increases, engineers and architects are exploring advanced composites and bio-based materials. These innovations not only enhance the structural integrity of PCC panels but also contribute significantly to reducing the carbon footprint associated with traditional concrete production.

One of the most promising trends is the integration of recycled materials into the PCC mix. By utilizing waste products such as slag, fly ash, and recycled aggregates, manufacturers can create panels that are not only more robust but also environmentally friendly. Additionally, advancements in nanotechnology are enabling the development of concrete with superior properties, such as increased water resistance and reduced permeability. This evolution in material science is pivotal for building structures that withstand harsh weather conditions while promoting sustainability in construction practices.

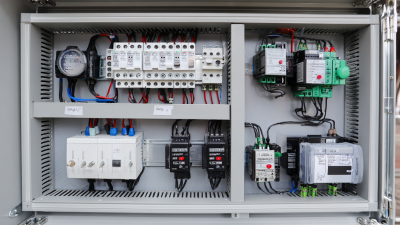

The integration of smart technologies, particularly artificial intelligence (AI) and the Internet of Things (IoT), is revolutionizing the way Power Control Center (PCC) panels operate. As these innovations pave the way for enhanced efficiency and productivity in the construction sector, PCC panels are becoming smarter and more responsive. AI algorithms analyze vast amounts of data generated by equipment and processes, optimizing performance and predicting maintenance needs. This shift allows for proactive decision-making, reducing downtime and improving overall operational efficiency.

In parallel with the advancements in AI, IoT applications enable real-time monitoring of equipment and facilities through interconnected devices. With sensors embedded in PCC panels, operators can gain insights into their systems' health, energy consumption, and environmental impact. This level of integration not only streamlines operations but also supports sustainable practices within the industry. As we approach 2025, the convergence of AI and IoT within PCC panels is set to redefine industry standards, driving impactful change across construction, mining, energy, and rail sectors.

| Innovation | Description | Expected Impact | Implementation Year |

|---|---|---|---|

| AI-Powered Monitoring | Integration of AI for real-time performance analysis. | Increased operational efficiency and predictive maintenance. | 2025 |

| IoT Connectivity | Utilization of IoT devices for remote access and control. | Enhanced monitoring and data collection. | 2025 |

| Smart Diagnostics | Automatic fault detection and reporting systems. | Reduction in downtime and maintenance costs. | 2025 |

| Enhanced Security Features | Advanced encryption and access control mechanisms. | Improved safety and data protection. | 2025 |

| Virtual Reality Interfaces | Use of VR for training and operational simulations. | Enhanced training effectiveness and operational safety. | 2025 |

| Predictive Analytics | Analytical tools for forecasting system failures. | Minimized risks and optimized maintenance schedules. | 2025 |

| Cloud Integration | Storing and processing data in the cloud for accessibility. | Greater flexibility and disaster recovery options. | 2025 |

| Energy Efficiency Technologies | Adoption of energy-efficient components and systems. | Reduced operational costs and environmental impact. | 2025 |

| Blockchain Technology | Utilizing blockchain for secure and transparent transaction data. | Improved traceability and accountability. | 2025 |

The future of energy efficiency is poised for significant advancements, particularly with the integration of PCC panels, which are set to reduce operational costs by 30% by 2025. These innovations in power conversion and management demonstrate the potential for optimized energy flow in various applications. The bidirectional energy flow capabilities between AC and DC offered by new technologies ensure that energy is managed more effectively, reducing waste and improving efficiency across systems, including electric vehicle substations and microgrids.

Furthermore, the push towards sustainability in infrastructure is influencing PCC panel designs, focusing on reducing carbon emissions in construction and operations. Strategies such as utilizing advanced materials and energy-efficient designs can drastically enhance the performance of PCC panels. As industries increasingly prioritize carbon abatement and energy efficiency, innovations in PCC technology will play a critical role in achieving net zero targets and fostering a new era of sustainable energy solutions.

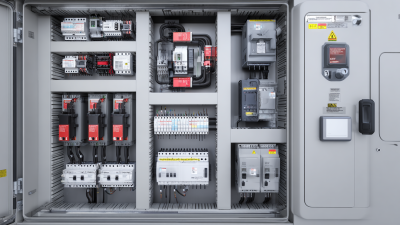

The landscape of Power Control Centers (PCC) is evolving rapidly, driven by the need for more adaptable and efficient solutions. Customizable designs in PCC panels offer a significant advantage as industries strive to meet diverse requirements. According to a recent report by Research and Markets, the global PCC market is projected to grow at a CAGR of 6.2% from 2023 to 2028, highlighting the increasing demand for modular solutions that can be tailored to specific operational frameworks. Modular PCC panels allow businesses to easily upgrade their systems, integrating new technologies without overhauling existing infrastructure.

Additionally, innovations in customizable PCC panels enable companies to address unique challenges across various sectors—be it renewable energy, manufacturing, or commercial real estate. The ability to configure layouts, functionalities, and even aesthetic features makes PCCs not just a functional component but a strategic asset. A study by MarketsandMarkets reveals that nearly 65% of industry leaders are prioritizing modular design in their procurement processes, reflecting a clear trend towards flexibility and responsiveness in panel solutions. As companies continue to adapt to the dynamic industrial landscape, customizable PCC designs will play a pivotal role in enhancing operational efficiency and meeting the growing complexity of energy management needs.

The integration of digital twin technology in PCC (Precast Concrete) panel production is set to transform maintenance and operational monitoring processes. By creating virtual replicas of physical assets, manufacturers can monitor real-time data and analyze performance metrics with unprecedented accuracy. This innovative approach allows for predictive maintenance, which not only reduces downtime but also extends the lifespan of the equipment involved in the panel manufacturing process.

Moreover, digital twins facilitate enhanced collaboration among various stakeholders throughout the production lifecycle. Designers, engineers, and maintenance teams can access a shared digital environment, enabling them to make informed decisions based on live data and simulations. This collaborative effort leads to improved efficiency in operations and a higher quality of finished products. As the industry adapts to these cutting-edge technologies, we can expect significant advancements in both productivity and sustainability in PCC panel production by 2025.