In the evolving landscape of electrical systems, a PCC Panel plays a crucial role. The term "PCC Panel," or Power Control Center Panel, refers to a significant element in power distribution. According to a recent market analysis by Research and Markets, the global power distribution market is projected to reach $300 billion by 2025. This trend underscores the importance of efficient power management solutions.

A PCC Panel is designed to monitor, control, and distribute electrical power. This panel often integrates various components like circuit breakers, relays, and transformers. By centralizing control, it enhances operational safety and efficiency. However, despite advancements, many installations still face challenges. Issues like equipment redundancy and system integration often prevent optimal performance. Industry reports suggest that up to 30% of energy losses occur in less optimized systems.

Understanding the functionalities of a PCC Panel can drive improvements. Implementation can lead to measurable outcomes in energy efficiency. However, it also introduces complexities that require careful consideration. Addressing these challenges is vital for maximizing the benefits of PCC Panels in today’s power systems.

A PCC panel, or Power Control Center panel, is a vital component in many electrical systems. It acts as a hub for controlling and distributing electrical power throughout a facility. This panel is designed to manage and monitor various electrical parameters, ensuring optimal performance and safety.

Inside a PCC panel, you will find circuit breakers, meters, and relays. These elements work together to protect circuits from overloads and faults. By displaying voltages, currents, and other vital information, operators can make informed decisions. Regular maintenance of these panels is essential, as neglect can lead to potential hazards.

Implementing a PCC panel requires careful planning. One must consider load calculations and system requirements. Its layout should promote accessibility for maintenance. However, deciding on the right components can be a daunting task. There is always room for improvement in design and functionality. Every installation presents unique challenges. Understanding these complexities can enhance reliability and efficiency.

This chart illustrates the performance metrics of a PCC (Power Control Center) panel over four quarters. The metrics include energy efficiency, operational uptime, and maintenance frequency.

A PCC panel, or Power Control Center panel, plays a crucial role in managing electrical power. It comprises several key components that ensure efficient operation. One essential part is the circuit breaker, which protects the electrical circuits from overloads. It acts as a switch, automatically disconnecting power when needed.

Another significant component is the busbar, a conductive material that distributes electrical power among various circuits. Busbars are often made from aluminum or copper and come in different shapes and sizes. They help minimize energy losses and improve the overall efficiency of the system. Additionally, control relays are used to monitor and control the flow of electricity through the panel.

Instrumentation is also critical. Ammeters, voltmeters, and temperature gauges provide real-time data on the operational status. These indicators can help identify problems early, but they sometimes overwhelm operators. It's important to process this information effectively to avoid overloads. Each component works together, ensuring the PCC panel operates smoothly, but frequent maintenance and checks are necessary. Without them, malfunctions can occur, causing significant issues.

A PCC (Power Control Center) panel plays a crucial role in industrial power management. It is designed to control, monitor, and distribute electrical power. The working mechanism of a PCC panel encompasses several components and functions that are essential for operational efficiency.

The heart of the PCC panel is its control system, which typically includes relays, circuit breakers, and metering devices. These components work together to ensure safe power distribution. According to a report by the International Energy Agency, proper power management can improve energy efficiency by up to 30%. The panel allows for real-time monitoring of electrical parameters. This data helps in identifying irregularities.

Another significant aspect is the integration of advanced technologies like IoT. These technologies enhance the panel's functionality and provide remote monitoring capabilities. However, not all facilities adopt these technologies. Some remain dependent on outdated systems. This gap highlights a need for improved awareness and training within various industries. Investing in modern PCC panels can facilitate energy savings and operational reliability.

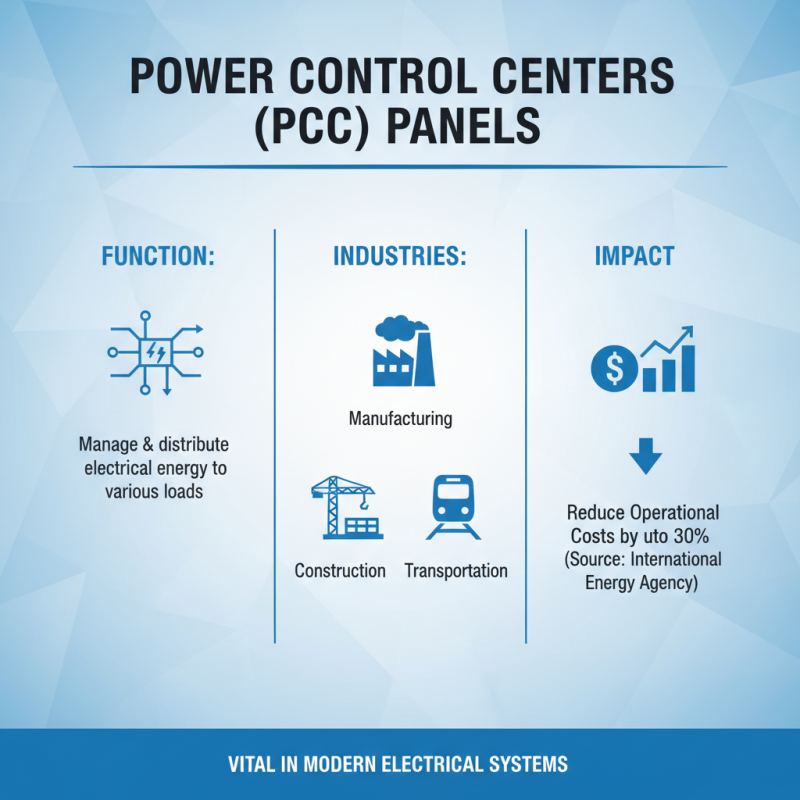

PCC panels, or Power Control Centers, are vital in modern electrical systems. These panels manage the distribution of electrical energy to various loads. The applications of PCC panels span across industries like manufacturing, construction, and transportation. In fact, a report by the International Energy Agency shows that effective energy management can reduce operational costs by up to 30%.

In manufacturing, PCC panels streamline power distribution, ensuring machinery operates efficiently. For instance, they help in managing motors and power loads, reducing downtime. This is crucial since unscheduled downtime can cost manufacturers millions. Data from the National Association of Manufacturers indicates that unplanned downtime costs companies, on average, $260,000 per hour. PCC panels can help mitigate these costs by enabling quicker responses to power issues.

The benefits don't stop there. PCC panels also enhance safety. They provide necessary protection against overloads and short circuits. However, there is a challenge. Poor installation or maintenance of these panels can lead to safety risks. A study from the National Fire Protection Association highlights that electrical failures are a leading cause of industrial fires. Regular inspection and skilled handling are essential to maximize the benefits of PCC panels while minimizing hazards.

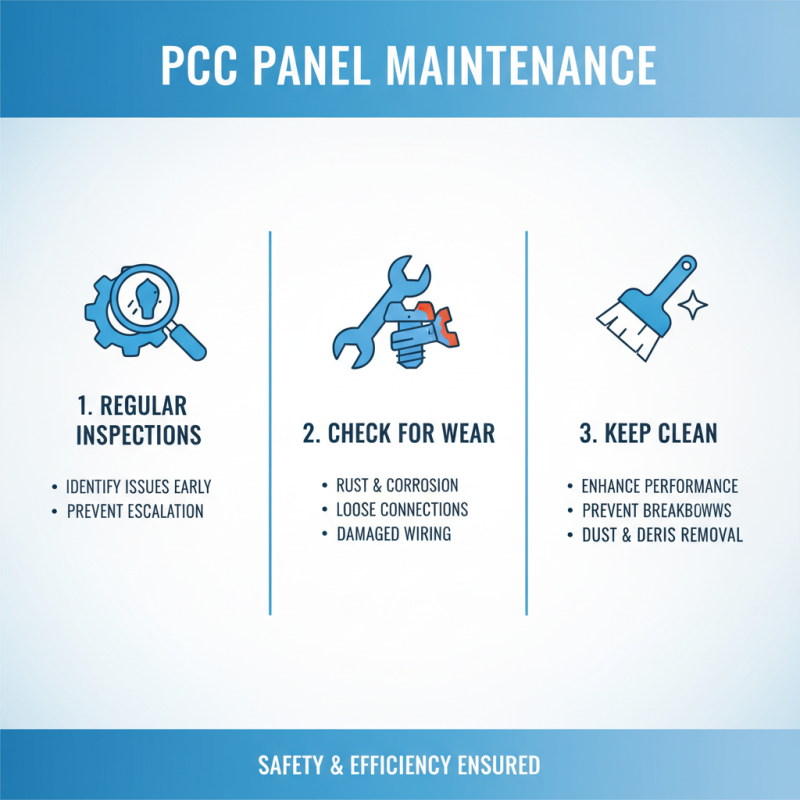

When it comes to PCC panels, maintenance is crucial for ensuring safety and efficiency. Regular inspections help identify issues before they escalate. Look for signs of wear, such as rust or loose connections. Keeping components clean enhances performance and prevents small problems from becoming larger.

Safety is paramount when dealing with PCC panels. Always ensure that power is turned off before performing maintenance. Use appropriate protective gear to mitigate risks. Many users overlook this step, which can lead to accidents. Additionally, training for staff is essential. Everyone must understand how to operate and maintain the panels safely.

Periodic testing is another vital aspect. Consider scheduling annual professional assessments. These can uncover hidden faults and ensure the system operates correctly. Document all maintenance activities. This creates a reliable history and assists with troubleshooting. Missed maintenance can lead to operational failures, costing both time and money.