As industry trends shift towards smart manufacturing and the Internet of Things (IoT), optimizing the integration of PLC in control panels has become paramount for enhancing automation systems. According to a report by MarketsandMarkets, the global PLC market is projected to reach $14.74 billion by 2025, growing at a compound annual growth rate (CAGR) of 5.8% from 2020. This growth underscores the critical role that Programmable Logic Controllers (PLCs) play in modern automation solutions, allowing businesses to improve efficiency, reduce operational costs, and enhance productivity.

The effective utilization of PLC in control panels facilitates real-time monitoring and control of various processes, streamlining operational workflows and supporting the shift towards Industry 4.0. Research from the International Society of Automation indicates that companies that have integrated advanced automation technologies, including PLCs, are witnessing an average productivity increase of 20-30%. This makes it essential for engineers and technicians to be well-versed in optimizing PLC configurations to fully leverage their capabilities.

In this guide, we will explore best practices and strategies to maximize the effectiveness of PLC in control panels, ensuring that organizations remain competitive in an increasingly automated landscape. By addressing design considerations, programming techniques, and maintenance protocols, we aim to equip stakeholders with the knowledge needed to harness the full potential of PLC-based systems in their automation endeavors.

Programmable Logic Controllers (PLCs) represent a pivotal technology in the realm of automation, particularly in control panels. At their core, PLCs are specialized computers designed to execute control operations in industrial environments. They offer flexibility, reliability, and the ability to handle complex tasks in real-time. Understanding the basic functioning of PLCs, including their input-output processing and programming environments, equips engineers and technicians to leverage their full potential in automating control systems.

The benefits of integrating PLCs into control panels are numerous. Firstly, PLCs enable streamlined operations by allowing for continuous monitoring and control of machinery. This real-time capability minimizes downtime and enhances productivity. Furthermore, they support a modular setup, permitting easy scalability and adaptation to evolving automation needs. As industries increasingly lean towards smart manufacturing, investing time in familiarizing oneself with the advantages of PLC technology becomes imperative, as it serves as a cornerstone for efficient and effective automation solutions.

When optimizing a PLC (Programmable Logic Controller) in a control panel, understanding the key components of the control panel is essential. Among the most critical elements are power supplies, input/output (I/O) modules, and communication interfaces. Power supplies ensure that the PLC and its associated components receive stable and adequate power, which is fundamental for reliable operation. A well-designed power management strategy will help avoid voltage fluctuations that can disrupt performance.

Input and output modules are equally important as they facilitate the connection between the PLC and the field devices. Choosing the right I/O modules—analog or digital—according to the specific application requirements is crucial. This not only enhances the responsiveness of the control system but also ensures accuracy in data processing. Additionally, incorporating communication interfaces that support various protocols can enhance connectivity and allow seamless integration into broader automation systems.

Finally, maintaining proper wiring and layout in the control panel is vital for optimizing PLC performance. Neat and organized wiring reduces the potential for electromagnetic interference and simplification of troubleshooting processes. By focusing on these essential elements, you can significantly improve the performance and resilience of PLC systems in automation projects.

| Component | Function | Optimization Tips | Importance Level |

|---|---|---|---|

| PLC Processor | Central control unit for automation | Choose a processor with higher speed and memory | High |

| Input/Output Modules | Interface between PLC and field devices | Use modular I/O to enhance flexibility | High |

| Power Supply | Provides necessary power for PLC operation | Select a reliable power supply with redundancy options | Medium |

| Communication Modules | Facilitates data exchange between PLCs and networks | Implement protocols like Ethernet/IP for optimized performance | Medium |

| Enclosure | Protects components in control panels | Ensure proper cooling and accessibility for maintenance | Low |

| Software | Programming and monitoring PLC operations | Use up-to-date software with user-friendly interfaces | High |

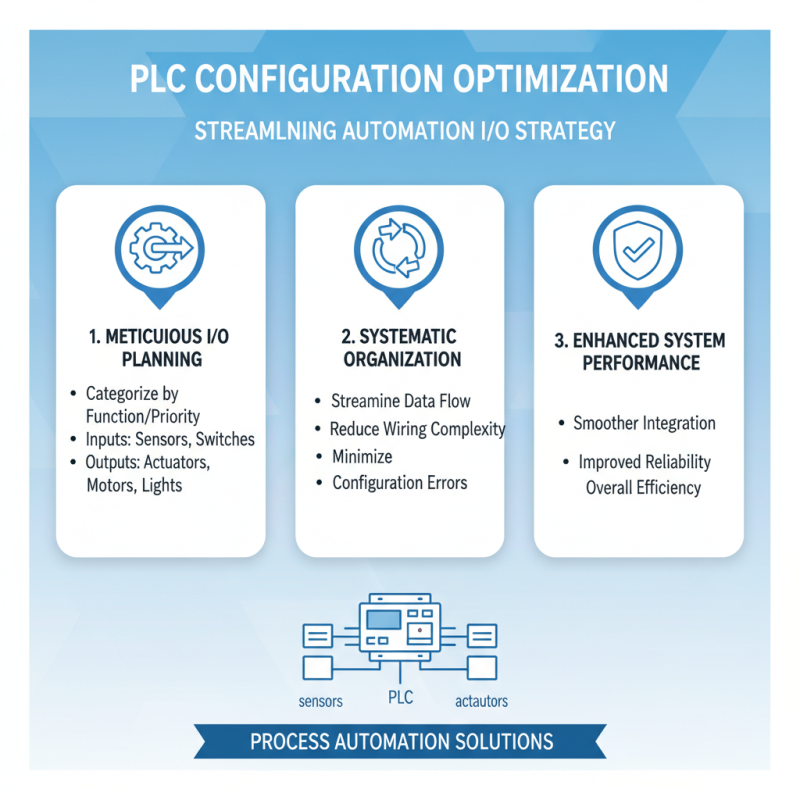

Effective optimization of Programmable Logic Controller (PLC) configuration is essential for enhancing automation systems in industrial environments. One key strategy involves meticulous planning of the I/O structure. It is crucial to categorize inputs and outputs based on their functions and operational priorities. By organizing I/O in a systematic manner, engineers can streamline the data flow, reduce the complexity of wiring, and minimize potential errors during the configuration process. This proactive approach ensures smoother integration with various sensors and actuators, enhancing overall system performance.

Another important strategy is regular monitoring and tuning of the PLC programs. Implementing diagnostic tools and performance metrics allows operators to evaluate the efficiency of the automation processes actively. By analyzing system logs and performance data, adjustments can be made to the logic and timing of control functions. This iterative process not only optimizes controller efficiency but also adapts to evolving operational demands. Ultimately, attention to these practices not only improves automation capabilities but also fosters a more reliable and responsive production environment.

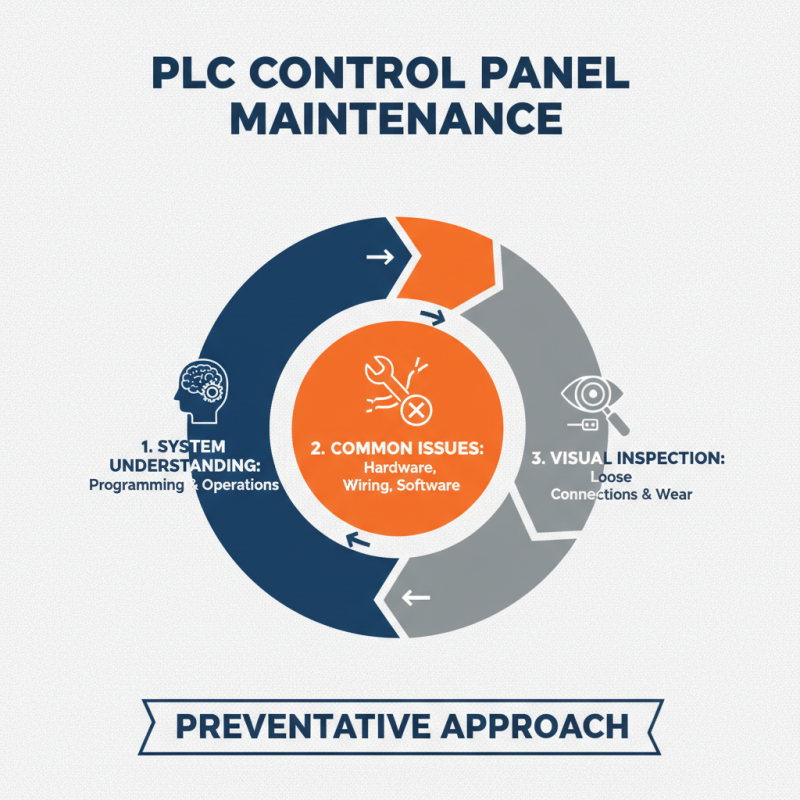

When troubleshooting and maintaining Programmable Logic Controllers (PLCs) in control panels, it's important to follow a structured approach. First, a thorough understanding of the control system is essential. This includes familiarizing yourself with the specific PLC programming and operational sequences. Common issues may arise from hardware malfunctions, wiring problems, or software errors. Regular visual inspections of the control panel for loose connections and signs of wear and tear can help prevent these problems from escalating.

Another key practice is the implementation of routine maintenance schedules. This should include checking the power supply, examining the cooling systems, and ensuring that the PLC firmware is up to date. Documentation plays a crucial role in this process; maintaining accurate records of past issues, resolutions, and regular checks helps build a comprehensive overview of the system's health. Moreover, using diagnostic tools and monitoring software can provide real-time insights into performance, thereby facilitating timely interventions before issues become critical.

The landscape of Programmable Logic Controller (PLC) technology is rapidly evolving, driving innovations that enhance automation processes across various industries. As we approach 2025, key trends are emerging that highlight the convergence of advanced technologies with traditional PLC systems. According to a recent industry report by MarketsandMarkets, the global PLC market is projected to reach $13.89 billion by 2025, indicating a compound annual growth rate (CAGR) of 5.9%. This growth is primarily fueled by the integration of IoT capabilities, enabling real-time data exchange and smarter decision-making processes.

One of the most significant trends in PLC technology is the incorporation of artificial intelligence and machine learning. These technologies allow PLCs to not only execute preprogrammed tasks but also analyze historical data and predict equipment failures, thus reducing downtime and maintenance costs. A study by Research and Markets noted that AI integration could enhance operational efficiency by up to 30%, demonstrating the potential for significant productivity gains.

Tips: To stay competitive, consider leveraging cloud-based PLC systems that facilitate remote monitoring and control. Additionally, investing in training for your technical team can ensure they are well-versed in the latest PLC innovations and best practices, enabling smoother transitions during upgrades. Finally, adopting a modular approach when designing control panels can enhance flexibility, allowing for easy scalability as your automation needs evolve.

This chart illustrates the projected advancements in PLC technologies over the next few years, focusing on key features that enhance automation efficiency.