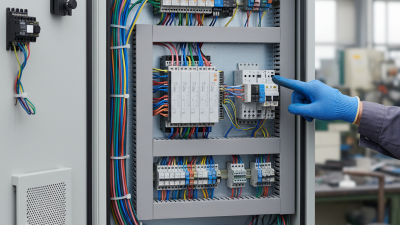

In the landscape of modern automation, the "Plc In Control Panel" has become indispensable. Industry expert Dr. Sarah Thompson emphasizes this by stating, “A well-designed PLC integrates seamlessly into control panels, enhancing efficiency.” Her words resonate clearly in today’s complex technological environment.

The importance of the “Plc In Control Panel” cannot be overstated. It provides streamlined communication between hardware and software. This integration allows for real-time monitoring, which is crucial for improving operational performance. Yet, not all systems embrace this technology effectively. Some fail to recognize its full potential. This oversight can lead to inefficiencies and increased downtime.

Furthermore, the shift towards automation requires adaptability. The "Plc In Control Panel" must be flexible enough to accommodate various inputs and outputs. However, some designs overlook the need for future scalability. It is essential to reflect on these shortcomings to move forward. Embracing PLC technology means acknowledging both its advantages and limitations. This recognition is vital for industries aiming to thrive in an ever-evolving landscape.

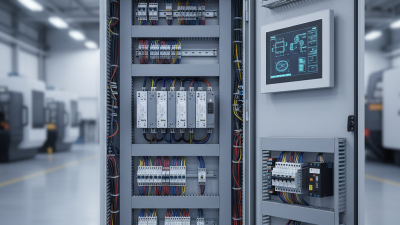

In modern automation systems, Programmable Logic Controllers (PLCs) play a vital role. They are the heartbeat of industrial control processes. According to a recent industry report, over 80% of manufacturing plants utilize PLCs to streamline operations. These systems reduce the need for human intervention, enhancing efficiency.

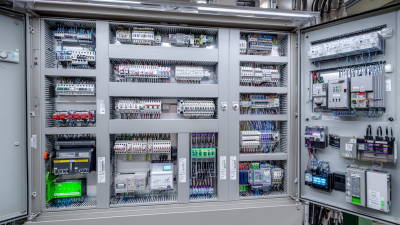

PLCs offer flexibility and scalability. They can easily adapt to changing production demands. The Switchgear market report indicates a projected CAGR of 4.5% for PLC usage in industrial automation. This growth highlights the increasing reliance on PLC technology to optimize both costs and performance. However, the challenge remains in integrating older systems with modern PLCs. Many facilities struggle with legacy equipment compatibility, leading to increased downtime.

A staggering 30% of companies face difficulties in PLC programming. This reflects a skills gap in the workforce. Training employees on effective PLC programming is critical for maximizing their potential. Moreover, while PLCs simplify processes, misconfigurations can lead to significant operational mistakes. Continuous improvement and investment in training are essential in harnessing the full power of PLCs while mitigating risks.

PLCs, or Programmable Logic Controllers, are vital for modern automation systems. They offer several key features that enhance efficiency. One standout feature is real-time data processing. This allows systems to respond quickly to changes. For example, in a manufacturing line, if a machine malfunctions, the PLC can immediately notify operators, minimizing downtime.

Another important aspect is modularity. PLCs can be easily expanded or modified as needs evolve. This flexibility proves beneficial during system upgrades. Instead of replacing the entire system, users can add new modules. It saves both time and resources.

Tips: Regularly update PLC software to improve performance and security. Make training a priority for operators. Knowledge of PLC functions can prevent errors and misconfigurations. Keep documentation handy. Having a printed or digital guide can assist in troubleshooting.

Despite their advantages, PLCs can have drawbacks. Configuration can be complex for inexperienced users. Misconfigurations might lead to unexpected behaviors in the system. It’s essential to test configurations thoroughly before full deployment. Proper planning and a bit of patience can go a long way.

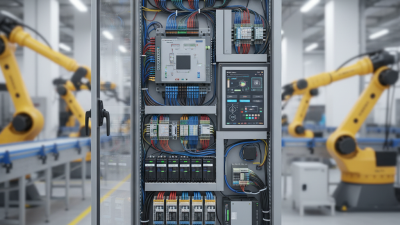

In recent years, the adoption of Programmable Logic Controllers (PLCs) has surged in industrial automation. According to a report by Markets and Markets, the PLC market is expected to reach $14.5 billion by 2027, growing at a CAGR of 5.2%. This growth reflects an increasing shift towards automation in manufacturing processes, as organizations strive for efficiency and reliability.

Statistics reveal that about 70% of manufacturers now incorporate PLCs into their systems. This widespread adoption is driven by the need for real-time data processing and enhanced control. Industries such as automotive and food production lead the way in PLC usage. They rely on these systems for streamlined operations and quality assurance.

However, the transition to PLCs is not without its challenges. Many companies face integration issues with existing equipment. Training is also crucial; nearly 30% of workers lack the necessary skills to operate advanced PLC systems. Addressing these gaps is vital for maximizing the potential of automation. As industries move forward, focusing on training and integration will be key.

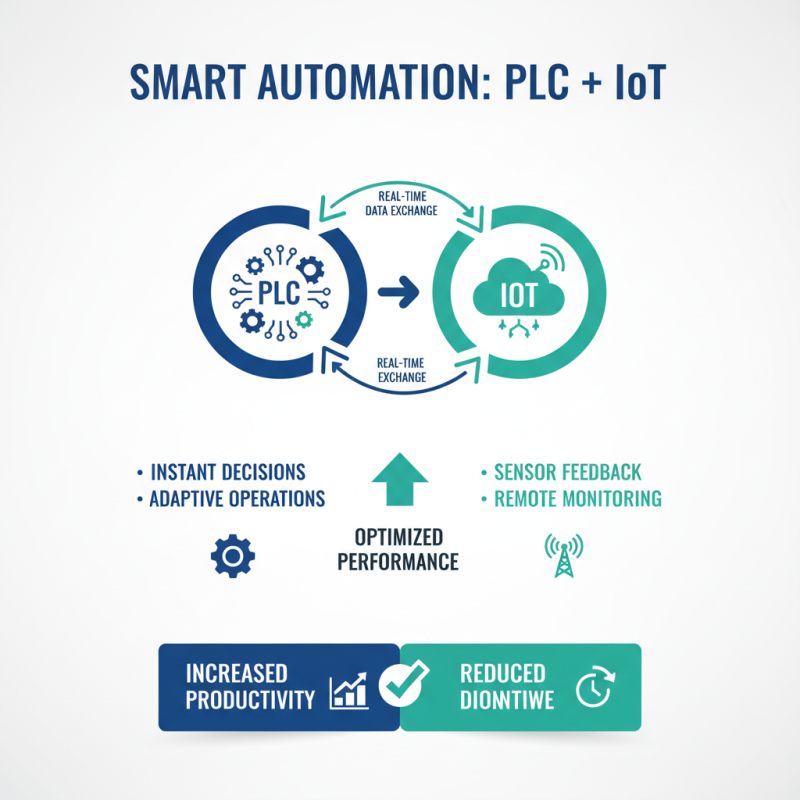

The integration of Programmable Logic Controllers (PLCs) with the Internet of Things (IoT) transforms how modern automation systems operate. This combination creates intelligent systems that optimize performance. Through real-time data exchange, PLCs can make instant decisions and adjust operations. Sensors connected to the IoT provide crucial feedback. This leads to increased productivity and reduced downtime.

However, not every company has seamlessly integrated these technologies. Some businesses struggle with data overload. They must sift through unnecessary information to find what truly matters. The complexity of managing multiple devices can overwhelm even seasoned engineers. Effective training and adaptable systems can ease this burden.

Additionally, reliability can be a concern. When many devices communicate, the risk of failure rises. A malfunction in one system may have a ripple effect. It is vital to ensure strong cybersecurity measures are in place. Tension exists between connectivity and security. Balancing these aspects remains a challenge for many automation teams.

In the realm of modern automation, Programmable Logic Controllers (PLCs) play a vital role. They provide flexibility and reliability. A comparative analysis reveals that PLCs outperform traditional relay-based systems. A 2022 industry report showed that PLCs can reduce downtime by up to 30%. They offer quick programming and adaptability, fostering efficient manufacturing processes.

While PLCs dominate, other control technologies like Distributed Control Systems (DCS) have their place. DCS can manage complex processes across large facilities. However, their initial setup can be costly and complex. Data indicates that users often face steep learning curves. Flexibility can become a double-edged sword. As companies evolve, identifying the best technology can be a challenge.

Moreover, the rise of IoT impacts control system dynamics. PLCs need to adapt to connect seamlessly with IoT devices. Industry experts predict that by 2025, over 50% of machinery will integrate IoT capabilities. This shift raises questions about how PLCs will remain relevant. Will they evolve, or will they be surpassed? The uncertainty prompts a need to rethink current systems and processes.

| Control Technology | Key Features | Pros | Cons | Typical Applications |

|---|---|---|---|---|

| Programmable Logic Controller (PLC) | Programmable, reliable, real-time control, robust | High reliability, flexibility, modularity | Costly, requires programming skills | Manufacturing automation, conveyor systems |

| Relay Control System | Electromechanical relays, hardwired logic | Simple, low initial cost | Inflexible, labor-intensive to modify | Basic on/off control, small-scale operations |

| Distributed Control System (DCS) | Centralized monitoring, decentralized control | Effective for large operations, good integration | Complexity, higher costs | Process industries (oil, gas, chemicals) |

| Industrial PC (IPC) | Computer-based control, advanced processing | High processing power, flexibility | High cost, requires IT skills | Complex applications, data-intensive tasks |