Setting up a PLC HMI control panel effectively is essential in modern automation. According to industry expert John Smith, "A well-designed control panel streamlines operations and enhances efficiency." His insights highlight the importance of thoughtful design.

When considering a PLC HMI control panel, clarity and functionality are paramount. Choose components that match your system needs. Ensure that the layout is intuitive for operators. The challenge lies in balancing complexity with usability. A cluttered panel can lead to mistakes, which can be costly.

Attention to detail makes a difference. Each button and display should have a purpose. Select the right screen size to ensure visibility. Test the system rigorously before deployment. This process often reveals unforeseen issues. Reflect on your design choices; constantly improve as technology evolves.

Programmable Logic Controllers (PLCs) and Human-Machine Interfaces (HMIs) are critical components in modern industrial automation. A recent study estimates that the PLC market will reach $10 billion by 2026, driven by the demand for enhanced manufacturing efficiency. Understanding these technologies simplifies the setup of a control panel, enabling real-time monitoring and control of machinery.

PLCs serve as the brain of a control system, executing programmed instructions. When integrating HMIs, operators gain visual access to critical data. An effective HMI can display alarms, trends, and system status. According to industry reports, improper HMI design can lead to up to 30% inefficiency in operations. Thus, attention to detail is crucial in selecting display layouts and interactive controls that align with operator needs.

However, challenges arise in configuring these systems. Miscommunication between PLC and HMI can lead to operational failures. It is essential to prioritize clear data flow. Recognizing the limits of technology helps avoid over-reliance on automation. Continuous training and feedback loops are necessary, ensuring users adapt and enhance system performance over time. Thus, the effective integration of PLCs and HMIs not only boosts productivity but also requires ongoing evaluation and improvement.

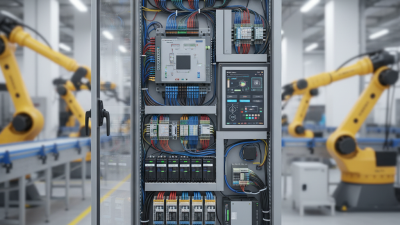

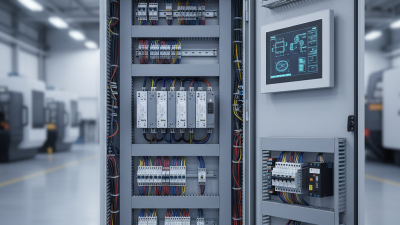

When setting up a PLC HMI control panel, selecting the right components is crucial. The components must work together seamlessly. This can be challenging but is essential for efficiency. Start with the controller. Ensure it meets your specific application needs. The size and complexity of your system will dictate the controller's capabilities.

The next aspect is the HMI. Choose one that offers clarity and user-friendliness. A good interface will minimize training time and errors. Look for features like touchscreens or customizable displays. These can enhance user experience significantly.

**Tips:** Pay attention to communication protocols. Make sure your components are compatible. Check documentation carefully. It can save you time later. Also, consider the layout of your panel. A cluttered panel can lead to mistakes. Simplicity matters.

In addition, think about power supply requirements. Overlooking this can cause issues. It's also critical to plan for future expansions. Design the panel for flexibility. This will help adapt to any changes in your system. Be ready to adjust your plans as needed. Always expect some amount of trial and error.

Setting up a PLC HMI control panel involves precise steps for optimal functionality. Begin with selecting a suitable enclosure. Ensure it can accommodate all components comfortably. An enclosure with proper sealing is crucial for industrial environments. According to a recent industry report, about 70% of control panel failures stem from inadequate environmental protection.

Next, organize the layout effectively. Position the PLC, HMI, and terminal blocks within easy reach. Aim for a clean wiring scheme. This reduces the chances of errors during installation. Studies show that poorly organized wiring can lead to a 50% increase in troubleshooting time. Space is key; overcrowding can cause heat issues.

Finally, thorough testing is essential before operational use. Run diagnostics on each component. Ensure communication between the PLC and HMI is seamless. It’s easy to overlook this stage, but it holds significant importance. Potential issues may only surface under specific conditions. Reflect on any overlooked steps. Continuous improvement should always be the goal in control panel setups.

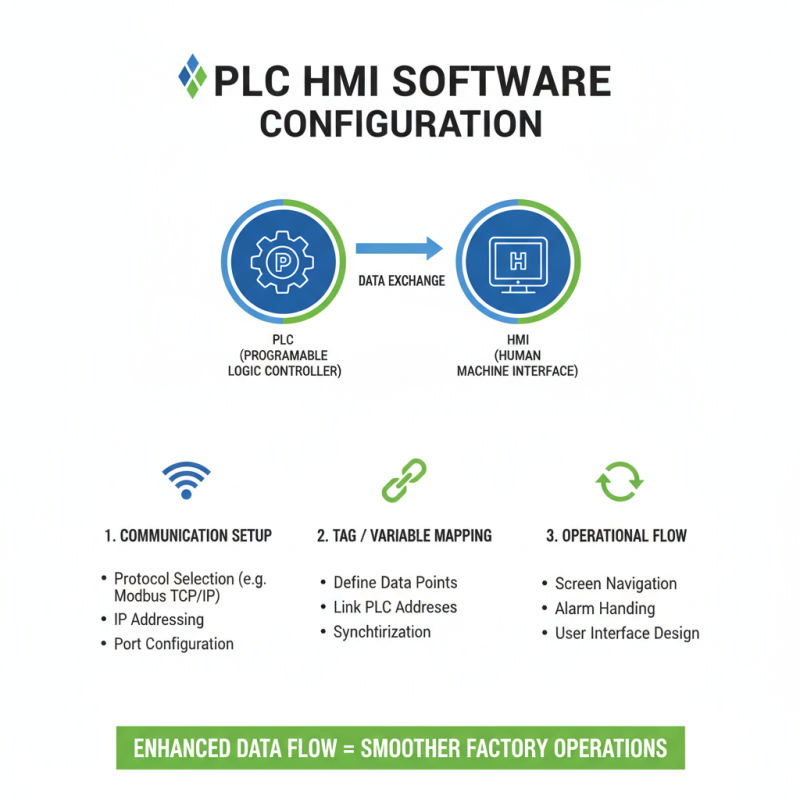

Setting up a PLC HMI control panel requires careful planning. Focus on software configuration for effective communication. Properly configured software enhances data exchange between the PLC and HMI. This ensures smoother operations on the factory floor.

Start by selecting compatible communication protocols. This step is crucial. Protocols like Modbus or Profibus can be effective. You need to ensure that both the PLC and HMI support the chosen protocol. Mismatches can lead to issues.

Tips: Always check the connection settings. Simple errors can cause significant problems. Regular testing should be part of your routine. Monitor data flow for any inconsistencies. Tune your configurations as needed.

Documentation is vital. Keep records of your setups and changes. It helps in troubleshooting later. This aspect is often overlooked. Remember, communication is not just about setup. It requires ongoing reflection and adjustment. By staying proactive, you can improve your control panel's performance.

Testing and troubleshooting a PLC HMI control panel is crucial for smooth operations. Start by verifying all connections. Loose wires or incorrect terminals can cause errors and malfunctions. Check the power supply. Ensure voltage levels are appropriate. A fluctuating supply can lead to erratic behavior.

In addition, run diagnostic tests on the software. Monitor the process visually using the HMI interface. Look for unexpected behavior in the system. Document any error codes that appear. This step is key for future troubleshooting. You might find issues that require a code update or reconfiguration of settings.

Always be prepared for unexpected outcomes. Sometimes, solutions may involve revisiting your initial setup. Reflect on your past mistakes to improve the process. This troubleshooting phase is where knowledge truly expands. Engaging with others in your field can also bring fresh perspectives. Seek feedback during this critical stage.