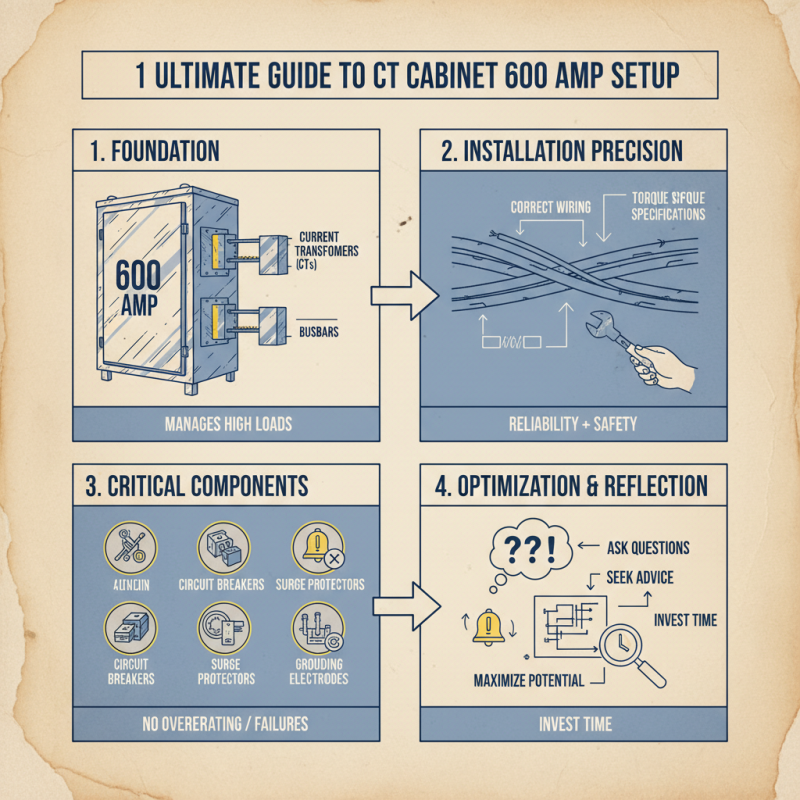

When setting up your electrical system, the Ct Cabinet 600 Amp is crucial. This guide walks you through the essential tips for an optimal setup. Understanding its significance helps ensure safety and efficiency.

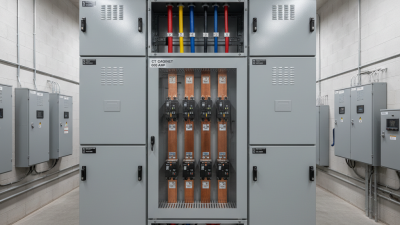

The Ct Cabinet 600 Amp manages high current loads effectively. It offers reliability but requires precise installation. Improper setup can lead to risks like overheating and equipment failure. Pay attention to each detail, from wiring to circuit breakers.

While many seek quick solutions, investing time in understanding the Ct Cabinet 600 Amp pays off. Ask questions and seek advice if unsure. Rushing this process can cause issues down the line. Take the time to reflect on your setup, ensuring you maximize the cabinet’s potential.

When setting up a 600 Amp CT cabinet, understanding its basics is crucial. A CT cabinet manages current transformers and ensures accurate readings. This is essential for monitoring electrical systems. The cabinet houses components that help protect equipment and enhance safety. Proper installation can prevent many issues.

Tips for your 600 Amp setup include choosing appropriate housing materials. Opt for robust options, resistant to harsh weather. Seal any gaps to prevent moisture ingress. Regularly inspect your cabinet for signs of wear. It’s too easy to overlook minor flaws, yet they can lead to bigger problems later.

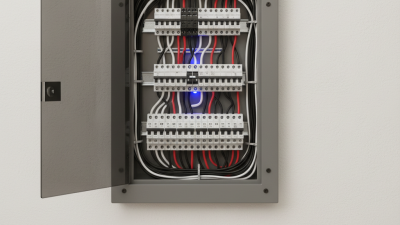

Consider cable management as well. Neat organization minimizes clutter and confusion. Label wires clearly to aid future maintenance. Good documentation will help if troubleshooting is needed later. Remember, a poorly planned cabinet can cause headaches down the line. Stay mindful of every detail to ensure long-term success.

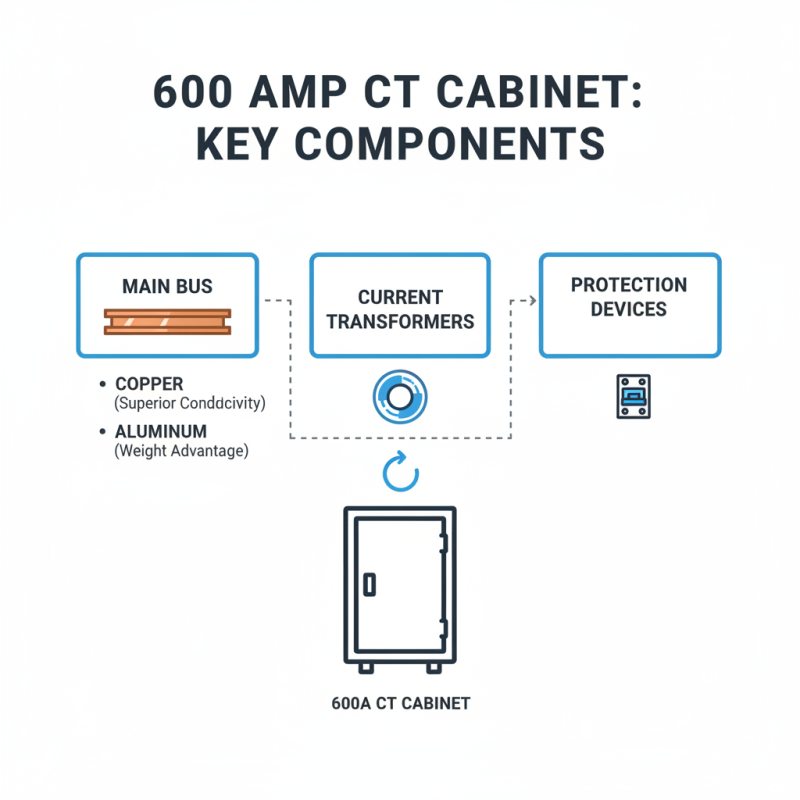

When setting up a 600 Amp CT Cabinet, understanding its key components is crucial. A typical cabinet consists of a main bus, current transformers, and protection devices. The main bus usually accommodates copper or aluminum conductors, which handle high current loads efficiently. According to industry reports, copper is preferred due to its superior conductivity, though aluminum offers weight advantages.

The current transformers (CTs) play pivotal roles. They help monitor the current flowing through the system. An ideal CT should maintain an accuracy level of 0.5% or better under rated conditions. Additionally, protection devices like circuit breakers are essential. They ensure safe operation by disconnecting in case of overload or fault. Industry standards highlight that a properly rated circuit breaker can avert up to 80% of electrical accidents.

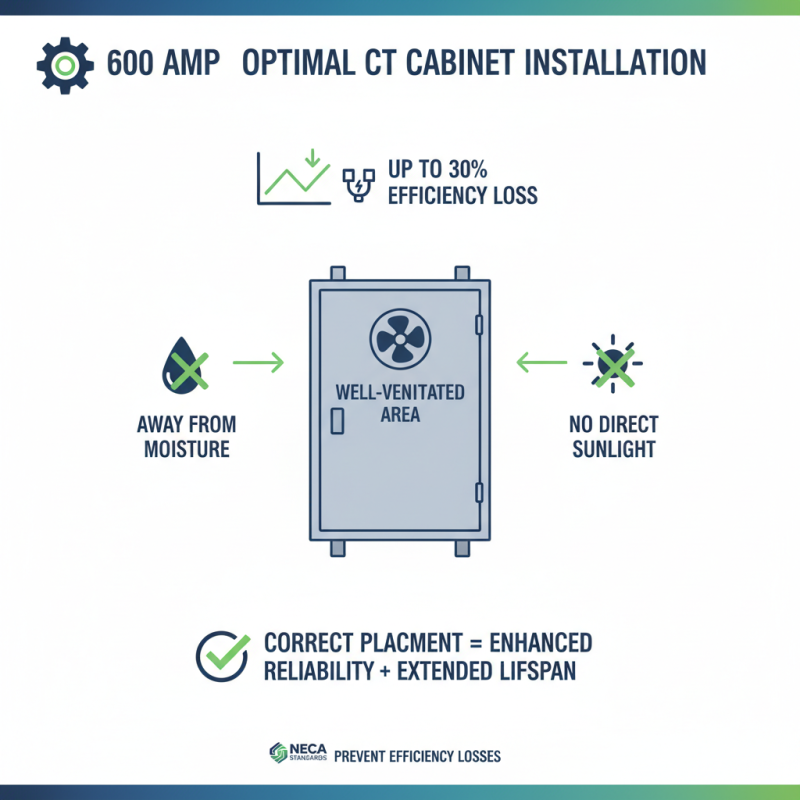

However, many installations overlook ventilation. Proper airflow prevents overheating, a common issue in densely packed installations. A study showed that 30% of electrical failures are linked to inadequate cooling. Moreover, while maintenance schedules can be tedious, they are often dismissed, leading to long-term complications. Regular checks on CTs and bus connections help catch issues early, ensuring uninterrupted operation.

Proper installation of CT cabinets is crucial for ensuring optimal performance, especially for high-capacity setups like the 600 Amp configurations. According to the National Electrical Contractors Association (NECA), improper installation can lead to significant efficiency losses, potentially up to 30%. Ensuring the correct placement is key. Set the cabinet in a well-ventilated area, away from moisture and direct sunlight. This can prolong the lifespan of your equipment and enhance its reliability.

It's essential to adhere to safety standards during the installation process. Regular checks on connections and insulation integrity are vital. A study from the Institute of Electrical and Electronics Engineers (IEEE) emphasizes that more than 25% of electrical failures stem from poor connections. Simple techniques, such as using advance connection methods and maintaining a clean installation site, can mitigate risks.

Consider the cable selection carefully. Cables should match the load requirements specified in the guidelines. Oversized cables can be costly, while undersized ones can cause overheating. Verify that the cabinet specifications align with the current requirements in real time. Implementing these strategies can lead to better efficiency. Stability is just as important. Regular audits and maintenance should be routine aspects of your operational plan to ensure lasting performance.

When setting up a 600 Amp CT cabinet, adhering to safety standards is crucial. The National Electrical Code (NEC) provides key guidelines. These codes help prevent hazards such as electrical fires and injuries. According to a 2022 report from the National Fire Protection Association, improper installation accounts for nearly 20% of electrical fires. Following NEC guidelines minimizes these risks significantly.

Grounding and bonding become essential in this setup. Proper grounding reduces the chance of electric shock. The Institute of Electrical and Electronics Engineers (IEEE) emphasizes that incorrect grounding remains a common issue. Their studies show that nearly 30% of electrical systems had grounding inadequacies. Regular inspections can catch these flaws.

Moreover, worker safety should not be overlooked. Personal protective equipment (PPE) is vital when working on any electrical cabinet. Reports indicate that using appropriate PPE reduces injury rates by about 50%. Additionally, documentation and labeling of equipment must be clear. Mislabeling or lack of documentation can cause errors. This may lead to dangerous situations, underscoring the need for attention to detail.

| Component | Description | Safety Standards | Installation Tips |

|---|---|---|---|

| CT Cabinet | A cabinet designed to house current transformers for metering and protection purposes. | IEEE C57.13, ANSI C12.1 | Ensure proper ventilation and accessibility for maintenance. |

| Current Transformers (CTs) | Devices that convert high current to a lower, proportional current for measurement. | UL 2808 | Verify wiring and connections before installation. |

| Fuses | Safety devices that protect circuits from overloads by breaking the circuit. | IEC 60269 | Select fuses rated for the application and install in a safe location. |

| Grounding | A safety measure to prevent electrical shock and ensure system stability. | NEC 250 | Use copper grounding rods and ensure proper connections to the cabinet. |

| Disconnect Switches | Switches used to isolate electrical equipment from the power source. | NEMA 250 | Mount in accessible locations and clearly label for operation. |

Proper maintenance of CT cabinets is essential for their longevity and efficiency. Regular inspections can prevent small issues from becoming larger problems. Checking the electrical connections helps identify potential failures early. Dust and debris accumulation can hinder airflow. Clean the cabinets regularly to ensure that cooling systems function properly.

Temperature control is another critical aspect. High temperatures can damage components. Consider installing temperature monitoring systems that alert you when thresholds exceed normal levels. Using quality ventilation can also reduce overheating risks. Addressing these elements promptly is crucial.

Lastly, don’t overlook software updates for any monitoring systems. Outdated software might expose vulnerabilities. Regular updates enhance security and functionality. Track all maintenance activities in a log. This helps you assess patterns over time. Remember, a proactive approach is more effective than reactive measures.