In the rapidly evolving landscape of technology, selecting the right Electronic Cabinets has become a critical consideration for businesses and organizations across various sectors. Experts in the field emphasize that the choice of an electronic cabinet can significantly impact the efficiency and safety of electronic systems. Renowned industry expert, Dr. Emma Thompson, states, "The right Electronic Cabinets not only protect sensitive equipment but also enhance operational performance and reliability."

As organizations increasingly rely on sophisticated electronic systems, the need for suitable electronic cabinets that meet specific requirements becomes paramount. Factors such as environmental conditions, size constraints, and accessibility must be meticulously evaluated to ensure optimal functionality. In a world where technology is advancing at breakneck speed, the importance of choosing the right Electronic Cabinets cannot be overstated.

In this article, we will explore the top considerations when evaluating options for Electronic Cabinets, providing insights that will guide decision-makers in making informed choices that align with their organizational needs and technical specifications.

When selecting electronic cabinets, it is crucial to consider various key factors that ensure optimal performance and reliability. According to a recent industry report by MarketsandMarkets, the global market for electronic enclosures is projected to reach $12.96 billion by 2025, underscoring the growing importance of choosing the right cabinets for specific applications. One of the primary considerations is the material of the enclosure. Common materials such as steel, aluminum, and plastic each offer distinct advantages in terms of strength, weight, and resistance to environmental factors. For instance, steel cabinets are known for their robustness and security, while aluminum offers lighter weight and better thermal management.

Another critical factor is the cabinet's cooling capabilities. In the same report, it was noted that inefficient thermal management can lead to product failures, which highlights the necessity for appropriate ventilation and cooling strategies in cabinet design. The integration of features like fans or heat exchangers can enhance performance, especially in high-density electronic environments. Moreover, the cabinet size and configuration must align with the electronic equipment being housed—ensuring adequate space for components, easy access for maintenance, and effective cable management. By assessing these factors, businesses can better tailor their electronic cabinets to meet their operational needs while enhancing overall efficiency.

When selecting electronic cabinets for your specific needs, it's essential to understand the various types available to ensure optimal functionality and safety. One common type is the server cabinet, specifically designed to house networking equipment and server racks. These cabinets usually feature ventilation systems to maintain a suitable temperature for sensitive electronic components, as well as lockable doors to secure the equipment from unauthorized access.

Another option is the AV cabinet, tailored for audio-visual equipment. These cabinets often come with adjustable shelves and cable management systems that help organize various devices like DVD players, gaming consoles, and speakers efficiently. Many AV cabinets also feature glass doors that allow visibility of the equipment while still providing protection from dust and accidental impacts.

For smaller electronic devices, wall-mounted cabinets may be an ideal choice. They save floor space and can be installed in various locations throughout a home or office. These cabinets typically have a modern design and are perfect for housing routers, switches, and other compact devices while keeping them accessible and well-organized. Understanding these different types of electronic cabinets will help in selecting the right one that fits both your aesthetic and functional requirements.

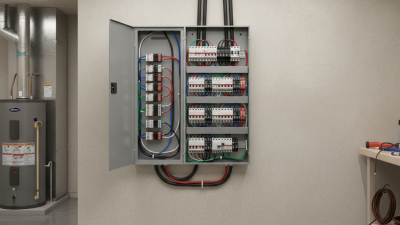

This chart illustrates the key considerations for selecting electronic cabinets based on different features.

When selecting an electronic cabinet, one of the most crucial aspects to consider is the size and space it will occupy in your environment.

Start by measuring the area where you plan to install the cabinet, ensuring you account for not just the footprint but also vertical space.

This will help you avoid purchasing a unit that is too large or too small for your needs. Remember, adequate airflow is vital for the operation of electronic devices,

so leaving room for ventilation around the cabinet is essential.

Additionally, think about the dimensions of the equipment you plan to store. Electronic cabinets come in various configurations, and selecting one that comfortably fits your devices

without cramping them will extend their lifespan.

Consider future expansion—if you anticipate adding more devices down the line, opting for a slightly larger cabinet can save you from the hassle of upgrading sooner than expected.

By evaluating both the physical space available and the specific needs of your equipment, you can make a more informed decision that balances

practicality and functionality.

When it comes to selecting electronic cabinets, the choice of materials plays a crucial role in ensuring both durability and functionality. According to a report by the Frost & Sullivan research group, the demand for robust electronic enclosures has increased significantly, with predictions for the market to reach $20 billion by 2025. This growth is driven by advancements in technology and the need for safeguarding sensitive electronic components. Therefore, selecting materials that can withstand environmental factors, such as temperature fluctuations and moisture, is essential for long-term performance.

Among the commonly used materials for electronic cabinets, steel and aluminum stand out for their strength and resilience. Steel, with its exceptional tensile strength, provides superior protection against physical impacts, making it a preferred choice for industrial applications. In contrast, aluminum is favored for its lightweight properties, which allow for easier handling and installation, while still offering substantial protection against corrosion. A study from MarketsandMarkets indicates that aluminum cabinets are expected to capture a significant market share due to their increasing use in outdoor applications where weather resistance is paramount.

Furthermore, the selection of materials should align with the specific needs of the intended use. For instance, anti-static materials are critical in environments where electronic components are sensitive to static electricity. According to the ESD Association, approximately 30% of all electronic failures are attributed to electrostatic discharge, emphasizing the importance of material selection in preventing such occurrences. By understanding the specific requirements of their applications, businesses can optimize their choices and enhance the reliability of their electronic equipment.

| Material | Durability Rating | Functionality | Best Use Case |

|---|---|---|---|

| Steel | High | High security, heat resistance | Industrial environments |

| Aluminum | Medium | Lightweight, good corrosion resistance | Electronic equipment |

| Plastic | Low | Versatile, lightweight | Home use, small electronics |

| Wood | Medium | Aesthetic appeal, good insulation | Office furniture, home decor |

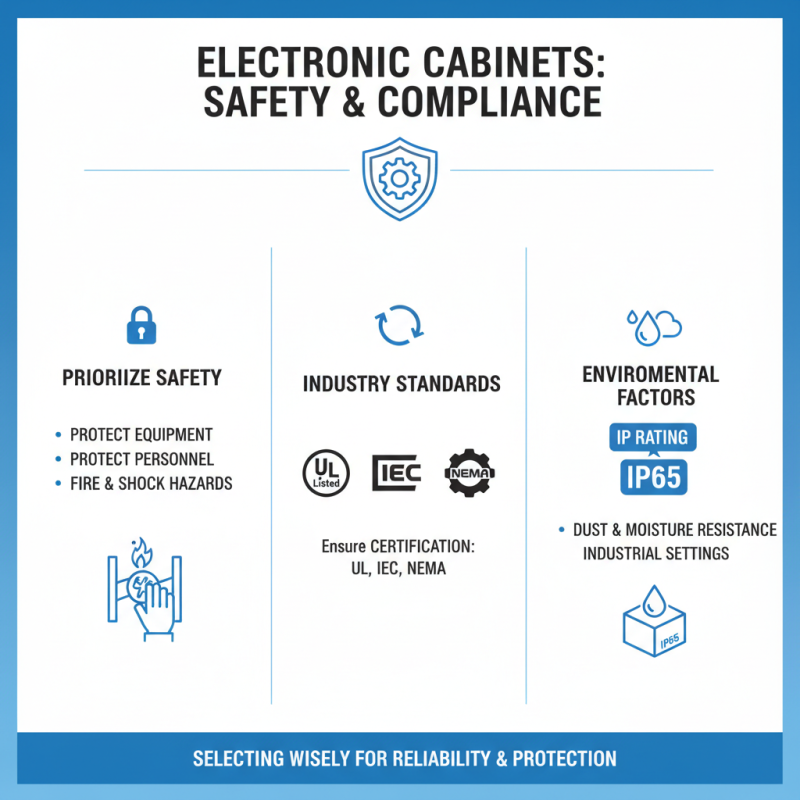

When selecting electronic cabinets, prioritizing safety features and compliance standards is crucial. Electronic cabinets are designed to protect not only sensitive equipment but also personnel working around them. Look for cabinets that meet industry-specific regulations such as UL, IEC, or NEMA standards. These certifications ensure that the cabinets offer adequate protection against electrical shock, fire hazards, and environmental factors. For instance, IP ratings can indicate how well a cabinet protects against dust and moisture, which is essential in industrial settings.

Tips: Always verify that the electronic cabinets you consider have been tested for safety under real-world conditions. Checking the documentation for compliance with safety standards can help you avoid potential risks.

Moreover, consider the cabinet's design for ensuring proper airflow and thermal management. Poor ventilation can lead to overheating, which may compromise both equipment functionality and safety. Cabinets with features like built-in fans, vented doors, and adequate spacing should be prioritized.

Tips: Regular maintenance checks and monitoring of temperature levels within the cabinets can help maintain optimal performance and safety. Investing in cabinets that allow for easy modification and upgrades can also help in adapting to changing compliance requirements over time.