In the evolving landscape of industrial automation, the importance of the Motor Control Cabinet cannot be overstated. Renowned industry expert John Smith once noted, “A well-designed Motor Control Cabinet is the heart of operations.” This statement captures the essence of these crucial components. Motor Control Cabinets house essential equipment for managing motors and electrical systems, ensuring safe and efficient operation.

As technology advances, the features embedded in Motor Control Cabinets are becoming increasingly sophisticated. From improved thermal management to enhanced safety protocols, these cabinets play a vital role. Flexible designs and diverse applications cater to various industries, from manufacturing to energy. The right cabinet can optimize performance and extend equipment life.

However, the constant push for innovation may lead to overlooking critical details. Not every Motor Control Cabinet is built for all environments. An ill-suited choice can cause inefficiencies or even hazardous situations. Reflection on specific needs is necessary to ensure that the selected cabinet meets all operational demands while maintaining safety standards.

Motor control cabinets (MCCs) play a crucial role in industrial automation. These cabinets house the electrical components needed to control motors. They protect personnel while ensuring machinery operates efficiently. According to recent industry reports, the global market for MCCs is expected to grow by 5.4% from 2024 to 2029. This growth reflects their importance in various applications.

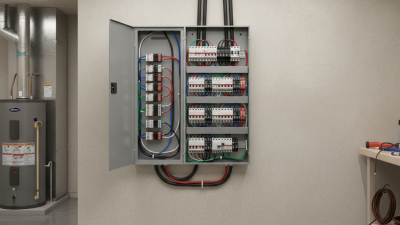

MCCs provide centralized control for multiple motors, making operation easier. They are often used in manufacturing, chemical processing, and water treatment industries. Each application demands specific features, like safety interlocks or variable speed drives. However, not all installations meet safety standards. Some cabinets lack adequate ventilation or thermal management. This oversight can lead to equipment failures.

Tips: Regular maintenance is essential. Inspect circuits for wear or damage. Ensure proper ventilation to prolong the lifespan of components. Consider modular designs for future scalability, but be cautious. Modular systems can lead to increased complexity. Evaluate whether your team can manage such systems effectively. Prioritize staff training on operational procedures and safety protocols. This investment aids in reducing errors and enhances operational efficiency.

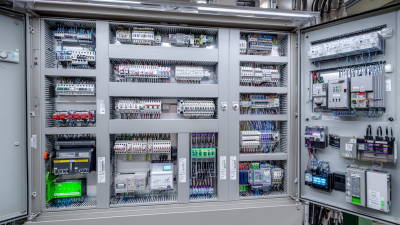

Efficiency and safety are crucial in motor control cabinets. The latest designs focus on optimizing energy use while ensuring reliable operation. According to a recent industry report, efficient motor control systems can reduce energy consumption by up to 30%. This benefit is vital for industries looking to cut operational costs and enhance sustainability.

Safety features in modern cabinets are also paramount. Improved thermal management systems prevent overheating. Enhanced circuit protection mechanisms help mitigate risks of failure. A study revealed that facilities with advanced safety features see a 25% reduction in equipment failure rates. However, not all manufacturers prioritize these elements, leading to inconsistent performance across products. Users need to carefully evaluate options to achieve the best blend of efficiency and safety.

Furthermore, it's important to address that some cabinets may lack sufficient diagnostic capabilities. This can hinder the identification of issues before they escalate. Regular evaluation of the chosen cabinet's technological advancements is essential. Companies might discover they are falling behind in efficiency metrics due to outdated technology. Addressing this gap is critical for maintaining competitive operations in today's energy-conscious environment.

This chart illustrates the key features and efficiency ratings of various motor control cabinets for 2026. It compares the efficiency and safety ratings based on industry standards.

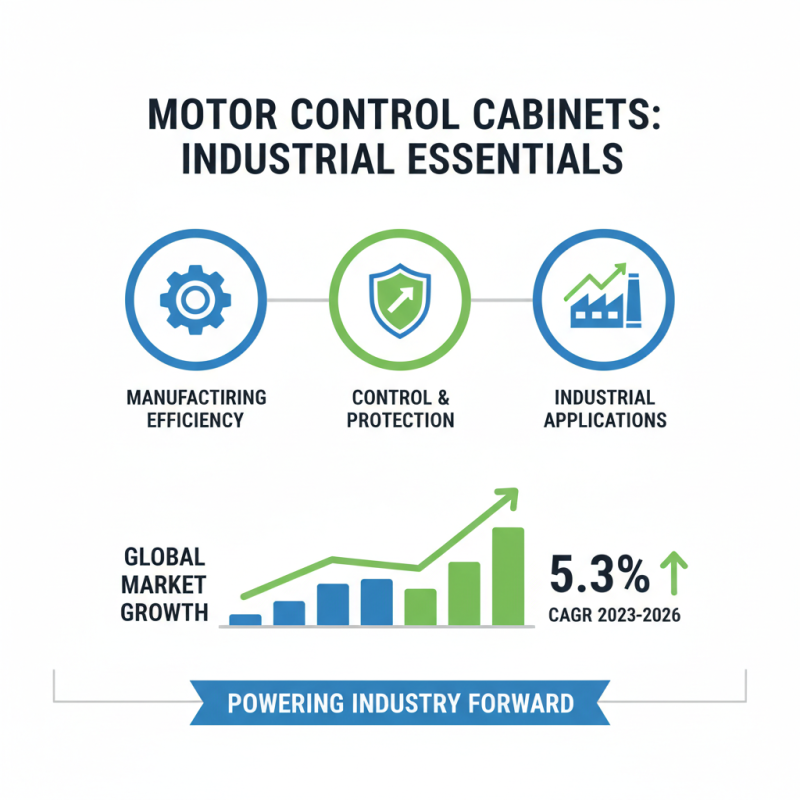

Motor control cabinets (MCCs) play a critical role across various industries. They provide essential control and protection for motors and equipment. In manufacturing, MCCs manage operations efficiently. According to the latest industry reports, the global motor control cabinet market is projected to grow at a CAGR of 5.3% from 2023 to 2026. This growth highlights their importance in industrial applications.

MCCs find applications in sectors like oil and gas, power generation, and water treatment. In oil and gas, they control pumps and compressors. In power generation, they help regulate turbines. Water treatment plants use them to manage filtration systems. These cabinets enhance reliability, yet not all installations meet optimal standards. Many facilities still use outdated technology, leading to inefficiencies.

Tips: Regular maintenance is vital for MCCs. Inspect connections and wiring periodically. An outdated cabinet can cause unexpected failures. Upgrading to modern solutions can save costs in the long term. Focus on energy efficiency in your designs to reduce operational costs.

The new 2026 motor control cabinets bring significant upgrades. Compared to previous models, they show enhanced efficiency and user-friendly interfaces. Notable advancements include improved energy consumption and compact designs. These features are critical for industries focusing on automation and control.

Many users appreciate better safety protocols. The 2026 models feature advanced circuit protection and are built with durable materials. This robustness can prevent failures during critical operations. However, it’s essential to consider the learning curve that comes with new technology.

Tips: Invest time in training staff on the new system. Regular maintenance can prolong cabinet life. Also, review your operational requirements closely before making equipment upgrades.

While new features are appealing, some users may find the integration challenging. Often, compatibility with existing systems may pose unexpected issues. It’s vital to assess current setups before committing to this upgrade.

The future of motor control cabinet design is rapidly evolving. Industry forecasts suggest that the market will grow substantially, expected to reach $9 billion by 2025. This growth is driven by increased automation and the demand for energy efficiency. Advanced technologies play a crucial role in this transformation.

One notable trend is the integration of digital technology. Smart cabinets equipped with IoT (Internet of Things) capabilities allow for real-time monitoring and control. Data analytics can optimize performance and reduce downtime. However, this complexity introduces challenges in cybersecurity. Protecting sensitive data should be a priority as more devices connect.

Sustainability is another emerging focus. Eco-friendly materials and energy-efficient designs are a necessity. An estimated 30% of energy usage in industrial settings is linked to motor operation. Companies face pressure to minimize their environmental impact. Balancing innovation with ecological responsibility is no small feat. Many organizations are still grappling with these changes.