When it comes to electrical systems, choosing the right Distribution Board is crucial. A Distribution Board distributes electrical power and serves as a safety mechanism. There are various types available, each designed for specific needs. This variety can be overwhelming.

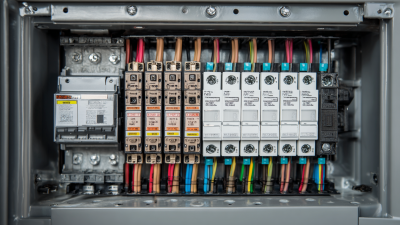

Understanding the different Distribution Board types is essential for making informed decisions. Each type has its advantages and drawbacks, which can impact your electrical setup. Some boards are ideal for residential spaces, while others suit industrial applications better. For example, a metal-clad Distribution Board offers durability, but it may also be costlier.

Selecting the right Distribution Board involves assessing your power requirements. Reflect on your energy consumption and the appliances you will use. It's easy to overlook the importance of this choice, but a wrong decision can lead to issues. Think carefully, as the right board will enhance safety and efficiency in your home or workplace.

Distribution boards serve as the brain of your electrical system. They route electricity from the main supply to various circuits. This approach helps ensure safety and proper functioning. According to recent industry reports, improper distribution can lead to power outages and equipment damage. A well-designed distribution board minimizes these risks.

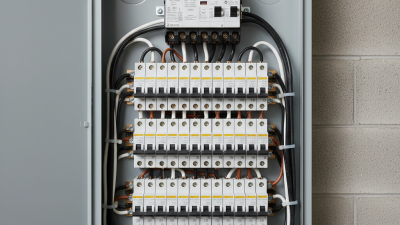

When choosing a distribution board, consider your specific electrical needs. For residential spaces, consumer units are commonly used. In commercial settings, panel boards are preferred for greater control. Understanding amperage rating is crucial. It determines the board's capacity to handle current loads. Ensure your choice aligns with your electricity consumption patterns.

Tips: Regularly inspect your distribution board. Look for signs of wear. If you encounter tripped breakers frequently, it might indicate overload. Always consult a professional for significant adjustments. Remember, poorly managed distribution boards can cause hazardous situations. Take time to review your setup frequently.

This chart represents the different types of distribution boards and their corresponding functionalities. Each type is characterized by its common application and efficiency levels.

When considering distribution boards, it's essential to understand their various types and applications. Panel boards are widely used in residential settings. They distribute electricity to various circuits. A report from the International Energy Agency indicates that nearly 80% of homes rely on these boards for electrical management. Residential panel boards typically include circuit breakers and fuses. They are designed for safety and ease of maintenance.

Then, there are motor control centers, commonly found in industrial applications. These boards manage and control motors efficiently. A study from the National Electrical Manufacturers Association highlights that motor control centers can reduce energy consumption by up to 20%. This efficiency pays off over time, but installation can be complex. It might require specialized knowledge, which isn’t always available on-site.

Switchboards function differently as well. These serve larger loads and often cater to commercial buildings. Data from the U.S. Department of Energy reveals that improperly maintained switchboards can lead to energy losses. Regular inspections are crucial, yet many facilities neglect this. Understanding these differences is vital for making the right choice to meet specific electrical needs.

When choosing a distribution board, consider several key factors. The type of electrical load in your home or facility will influence your decision. According to a report by the International Electrotechnical Commission, nearly 70% of electrical fires are linked to faulty distribution boards. Ensuring that your board meets local safety standards is crucial.

You must also think about the size and design of the distribution board. A compact design can save space. A study from the National Electrical Manufacturers Association states that a well-optimized distribution board can reduce installation time by up to 30%. However, overloading can lead to serious risks. Always calculate your current requirements accurately.

Lastly, consider future expansion. More equipment may be needed later. Leaving room for additional circuit breakers can save time. Some installations overlook this aspect. This oversight may lead to a lack of flexibility in the future. A careful selection process now can prevent issues later on.

When installing a distribution board, safety should be your top priority. Use non-corrosive materials for wiring. Research shows that nearly 70% of electrical faults come from poor connections. Always double-check connections during installation. Ensure all components meet local safety standards. This basic precaution can prevent serious problems later.

Regular maintenance is equally crucial. Inspect your distribution board every six months. Look for signs of wear, such as discoloration or loose connections. Over 50% of electrical fires are caused by faulty wiring. Taking proactive measures can save lives and property. Dust and debris should be cleaned away regularly to prevent overheating.

Consider the load capacity when adding new circuits. Every additional appliance increases the strain on the board. Ensure your distribution board is not overloaded. Evaluate your power usage patterns. Sometimes, it's better to consult a professional than to risk your safety. Trust your instincts if something feels wrong. The cost of neglect can be catastrophic.

The safety standards for electrical distribution boards are critical in ensuring reliable power distribution. According to the International Electrotechnical Commission (IEC), over 80% of electrical accidents occur due to substandard wiring and distribution systems. Compliance with IEC 61439 standards is vital. This standard outlines performance and safety criteria for low-voltage switchgear and control gear assemblies.

Many installations overlook these compliance guidelines. This oversight can lead to equipment failure or hazards. A recent study revealed that buildings with certified distribution boards experienced 30% fewer electrical incidents compared to those without compliance certifications. Additionally, regular inspections and updates are critical. Aging infrastructure poses risks, as outdated boards may not meet modern safety standards.

Ultimately, selecting the right type of distribution board is not just about performance; it’s also about safety. Adhering to regulations reduces risks but requires ongoing diligence. Ignoring guidelines can lead to serious consequences, emphasizing the need for compliance in all electrical installations. Regular training and audits can greatly enhance safety practices in this sector.

| Distribution Board Type | Applications | Safety Standards Compliance | Key Features |

|---|---|---|---|

| Standard Distribution Board | Residential and commercial use | IEC 60439, NEC | Multiple circuit control, easy installation |

| Smart Distribution Board | Smart homes and energy management | IEC 61439, UL 908 | Remote monitoring, energy consumption tracking |

| Industrial Distribution Board | Manufacturing plants, factories | IEC 61439, NEMA | Heavy-duty construction, high capacity |

| Modular Distribution Board | Flexible installations, upgradeable systems | IEC 61439, ISO 9001 | Scalable design, easy component replacement |

| Weatherproof Distribution Board | Outdoor applications | IP66, IEC 60529 | Water and dust resistant, durable materials |