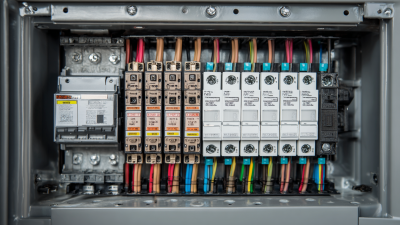

In the realm of industrial motor control, "Soft Start Panels" have emerged as a critical component in enhancing energy efficiency and extending the lifespan of motors. According to a report by the Department of Energy, implementing soft start technology can lead to energy savings of up to 30% in motor-driven applications. This technology allows for a gradual ramp-up of motor speed, reducing electrical inrush currents that typically lead to mechanical stress and wear, ultimately resulting in lower operational costs and improved reliability.

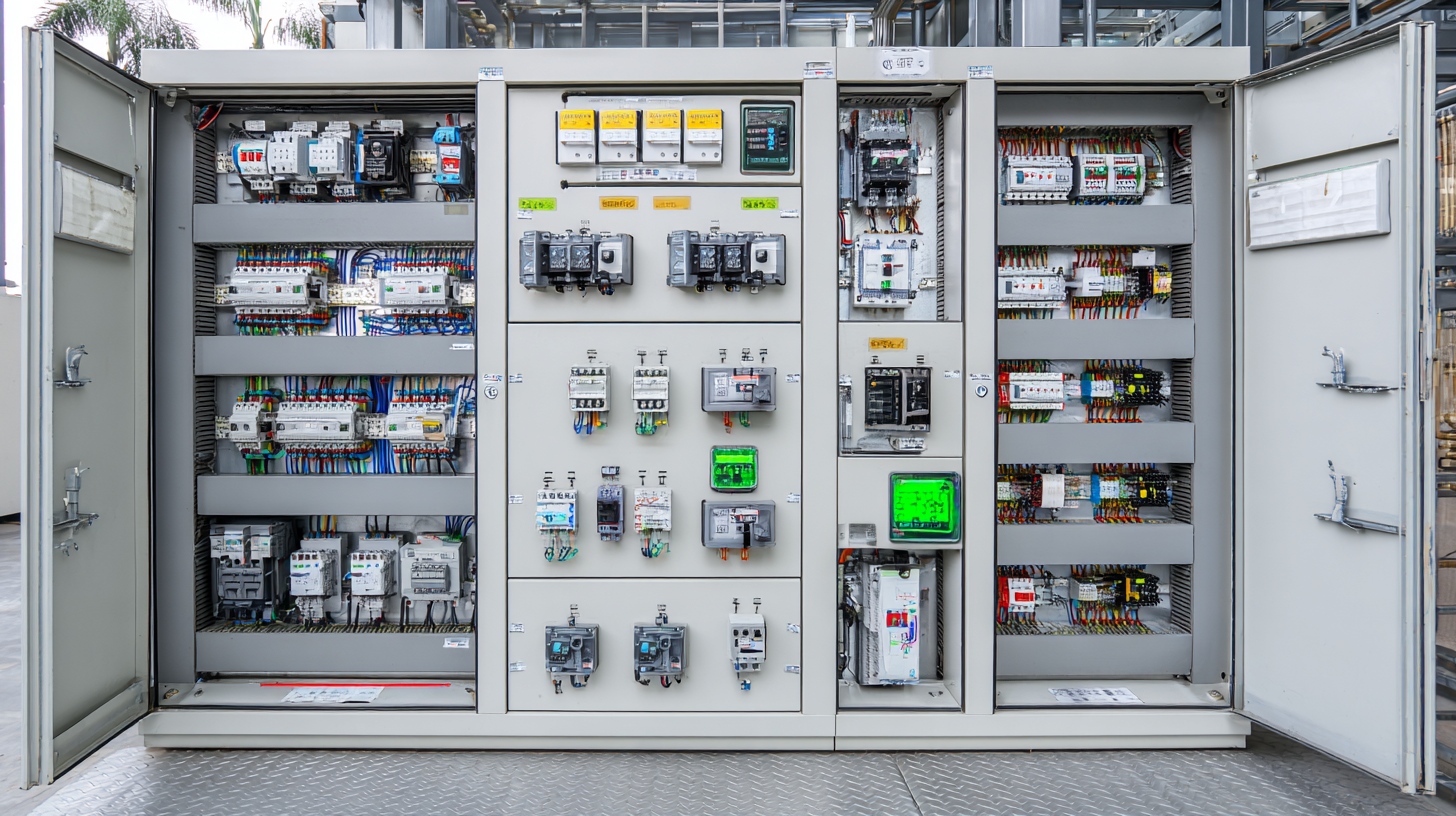

Soft Start Panels are particularly beneficial in applications where motors are frequently started and stopped, which is a common scenario in manufacturing and HVAC systems. The International Electrotechnical Commission (IEC) highlights that improper motor starting can lead to premature failures, increased maintenance requirements, and energy losses. By utilizing soft start technology, operators can significantly mitigate these risks, enabling smoother operations and enhanced performance in their systems.

As industries strive for sustainability and operational efficiency, the adoption of Soft Start Panels represents a significant advancement in motor control systems. With the growing emphasis on reducing energy consumption and minimizing environmental impact, understanding the advantages of these panels becomes essential for engineers and managers alike. The integration of soft starters into motor control strategies not only aligns with regulatory standards but also facilitates a more proactive approach to energy management, making them an invaluable asset in modern industrial applications.

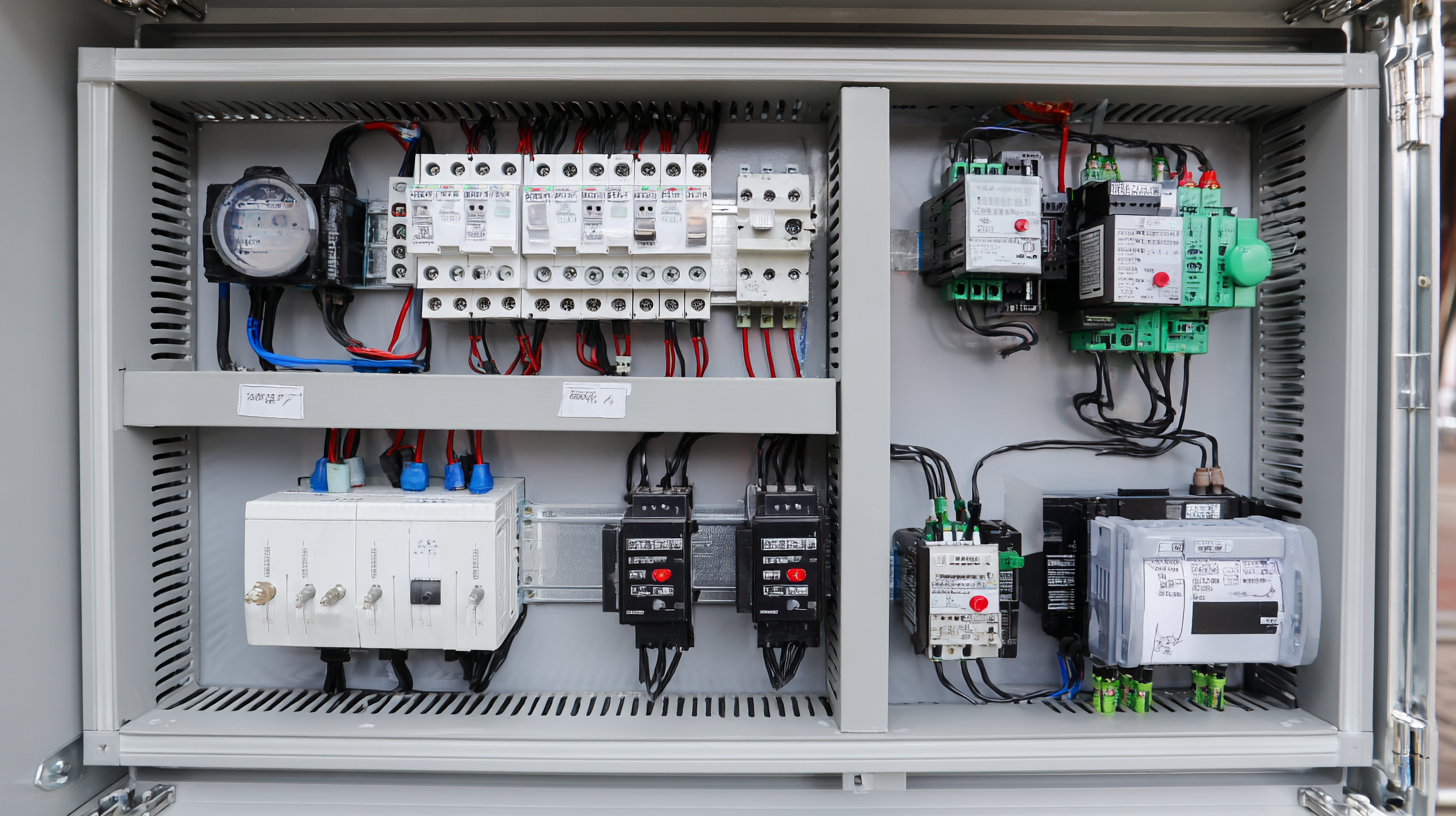

Soft start panels have emerged as essential tools for energy-efficient motor control, particularly in mitigating mechanical stress during motor startup. Traditional motor start methods often subject motors to high inrush currents, which can lead to significant mechanical stress and premature wear. According to a report from the International Energy Agency (IEA), implementing soft start technology can reduce mechanical stress by up to 60%, extending the lifespan of motors significantly.

In addition to prolonging equipment life, reducing mechanical stress translates into lower maintenance costs. A study by the Electric Power Research Institute (EPRI) highlights that organizations utilizing soft start panels have seen a reduction in maintenance expenses by up to 30%, primarily due to lower failure rates of components within the motors. This is especially advantageous in industries where reliability is critical and downtime can result in substantial financial losses.

TIP: To maximize the benefits of soft start panels, consider regular maintenance checks and keep an eye on motor load characteristics. Ensuring that the soft starter is correctly configured for the specific application can further enhance performance and efficiency.

TIP: When selecting a soft start panel, consult with manufacturers about the best options available for your specific motor type to optimize mechanical stress reduction and energy efficiency.

Soft start technology plays a pivotal role in enhancing energy efficiency within various industrial applications. By gradually ramping up motor speed, soft start panels reduce the initial current surge that typically occurs when motors are switched on. According to a report by the U.S. Department of Energy, utilizing soft starters can decrease energy consumption by up to 30% during the startup phase, contributing significantly to overall operational efficiency. With energy costs rising, industries are increasingly recognizing the potential of soft start panels to provide substantial savings while protecting motor systems from mechanical stress and premature wear.

Implementing soft start technology not only leads to direct energy savings but also enhances the longevity and reliability of motors. A study published by the Electric Power Research Institute indicated that soft starters can extend the lifespan of motors by 50% or more by minimizing mechanical shock and vibration during start-up. This not only reduces downtime associated with equipment failure but also cuts maintenance costs, making it an attractive option for manufacturers striving for efficiency.

**Tips:** When investing in soft start panels, consider integrating a monitoring system to analyze energy usage patterns and optimize performance. Regular maintenance checks can also help ensure that these systems operate at peak efficiency. Additionally, explore options that are compatible with variable frequency drives for optimal control in dynamic applications.

| Application Area | Initial Current Reduction (%) | Energy Savings (%) | Maintenance Costs Reduction (%) | Operational Lifespan Increase (%) |

|---|---|---|---|---|

| Pumps | 65 | 15 | 20 | 30 |

| Conveyors | 70 | 20 | 25 | 35 |

| Fans | 60 | 10 | 15 | 25 |

| Compressors | 75 | 25 | 30 | 40 |

| Mixers | 50 | 12 | 18 | 20 |

Soft start panels play a significant role in energy-efficient motor control, particularly in managing peak demand charges for businesses. By gradually ramping up the power supplied to electric motors, these panels prevent sudden spikes in electricity use that can lead to elevated demand charges on utility bills. According to a report by the U.S. Department of Energy, implementing soft start technology can lead to energy savings of up to 30%, making them a critical tool for companies looking to reduce operational costs amidst rising energy prices.

With grid operators warning of potential power shortages this summer, the focus on energy efficiency has never been more relevant. As energy consumption increases, particularly in peak periods, the need to mitigate demand spikes is crucial. Soft start panels not only lower the initial strain on electrical systems but also contribute to a more stable grid. Recent data indicates that optimizing motor control through such technologies can significantly alleviate pressure on the existing power infrastructure, aligning with broader efforts to enhance sustainability while addressing the challenges posed by fluctuating oil demand and regulatory constraints.

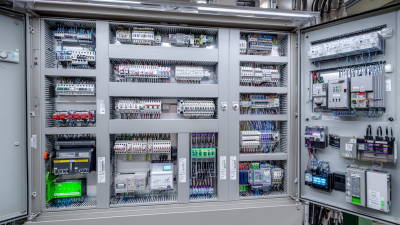

In the ever-evolving landscape of industrial automation, the choice between soft start panels and traditional motor controllers is pivotal for achieving energy efficiency. Soft start panels, known for their ability to gradually ramp up motor speed, significantly reduce electrical stress during motor startups. According to a report by the U.S. Department of Energy, implementing soft starters can lead to energy savings of up to 30% compared to traditional methods. This reduction not only extends the lifespan of motors but also mitigates voltage dips that can disrupt facility operations.

Moreover, traditional motor controllers often respond to load changes with abrupt starts, which can result in excessive mechanical wear and higher maintenance costs. Data from the Electric Power Research Institute (EPRI) indicates that systems using soft start technology can decrease overall operational costs by 15-20%. The smoother acceleration provided by soft start panels minimizes torque shock and prevents damage, making them a superior choice for industries where equipment longevity and reliability are critical. Thus, the comparative advantages of soft start panels extend beyond immediate energy savings, positioning them as a more sustainable solution for modern motor control applications.

Soft start panels play a crucial role in enhancing system reliability and reducing maintenance costs for motor control applications. By gradually ramping up the voltage and current delivered to a motor, these panels minimize the initial inrush current, which can otherwise cause mechanical stress and electrical surges. According to industry studies, implementing soft start technology can reduce mechanical wear by up to 70%, extending the lifespan of both motors and associated equipment. This translates into fewer breakdowns and reduced downtime, ultimately leading to significant cost savings.

Moreover, the recent launch of a new medium-voltage drive highlights the importance of efficiency and reliability in modern motor control systems. The air-cooled design, featuring advanced IGBT power stack architecture, aims to deliver high availability and low cost of ownership. Data suggests that investing in reliable motor control solutions, such as soft start panels and innovative drive technologies, can result in a 30% decrease in maintenance expenses over a system's lifecycle. By prioritizing these technologies, industries can ensure their operations remain efficient and cost-effective while minimizing unplanned maintenance events.