Choosing the right panel board is crucial for any electrical project. A panel board acts as the central hub for distributing electrical power. It connects the main electrical supply to various circuits throughout the building.

When selecting a panel board, consider factors like size, material, and number of circuits. Many overlook the importance of load capacity. It’s essential to calculate the total load to avoid circuit failures. Each project is unique, which makes choices difficult sometimes. It’s worth spending time to reflect on your specific needs.

A good panel board will enhance safety and efficiency. Yet, an improper choice can lead to problems. Always weigh your options carefully. After all, making the right decision now can save you from future hassles. Remember, a panel board isn’t just a box; it’s a critical safety component.

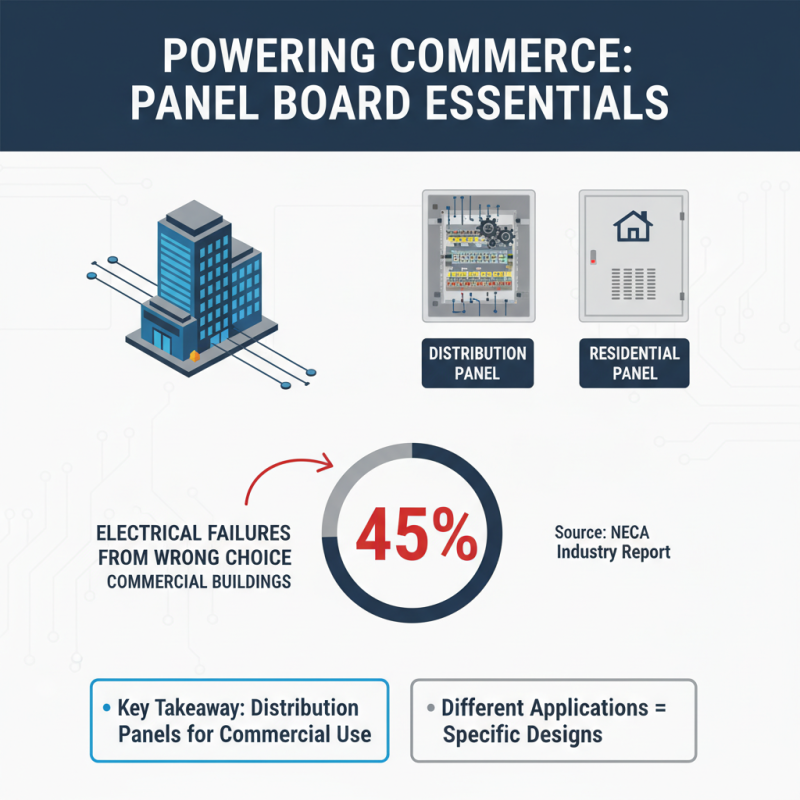

When selecting a panel board, it's crucial to understand the various types available. Different applications require specific designs. For instance, a distribution panel board is essential for commercial buildings. A recent industry report from the National Electrical Contractors Association indicates that 45% of electrical failures in commercial settings stem from improper panel board choices.

Furthermore, industrial applications may benefit from motor control centers, designed to handle high voltages and multiple circuits. The choice between a main panel board and a sub-panel also affects performance. Reports show that using the correct sub-panel can enhance efficiency by up to 25%. Yet, many projects fail to evaluate this correctly. Often, designs are either overspecified or undersized, leading to costly revisions.

The selection process isn't just about voltage ratings or amperage. It's vital to consider environmental factors. For example, panels used in outdoor settings must withstand moisture and corrosion. Many projects overlook such details. This oversight can lead to increased maintenance costs or even safety hazards. Balancing technical specifications with real-world conditions is a challenge many face. Being thoughtful in this stage can ensure better project outcomes.

Selecting the right panel board for your project is crucial. The right choice can enhance efficiency and safety. Consider durability and load capacity. Industry reports show that load-related failures are a significant cause of panel board malfunction. Analyze your project's demands carefully.

Tip: Assess the specific electrical load requirements. Panel boards should match system needs. A survey indicated that approximately 30% of projects suffer due to inadequate load analysis early on.

Safety features matter too. Look for circuit breakers and surge protection. Data shows that systems without these can have a failure rate of over 40%. Regular maintenance can help, but choosing a reliable panel board from the start is essential.

Tip: Conduct regular reviews of electrical specifications. Regular checks help avoid potential hazards. Remember, investing in a quality panel board saves time and money in the long run. Evaluate all options and trust your instincts. It’s an important decision that shouldn’t be rushed.

When selecting a panel board, understanding specifications is vital. Each project demands specific requirements. For example, a report by the Electrical Safety Foundation International (ESFI) notes that improper panel board selection leads to 30% more failures. This reflects the importance of evaluating load capacity, voltage rating, and environmental conditions before making a decision.

Tips: Always check the ampacity ratings. Failing to do so can result in overheating and potential fire hazards.

Pay close attention to material quality. A study by the National Electrical Manufacturers Association (NEMA) revealed that subpar materials can reduce lifespan by up to 40%. This could translate into unexpected costs later.

Finally, think about space. A cramped installation can lead to maintenance nightmares. Space considerations often get overlooked, but they are crucial for safe operation. Good planning can save time and money in the long run.

| Specification | Value | Importance |

|---|---|---|

| Voltage Rating | 120/240V, 480V | High |

| Amperage Rating | 100A, 200A, 400A | High |

| Number of Circuits | 12, 24, 42 | Medium |

| Panel Type | Main, Subpanel | Medium |

| Mounting Style | Surface, Flush | Low |

| Material | Steel, Plastic | Medium |

| Weatherproof Rating | NEMA 1, NEMA 3R | High |

| Compliance Standards | UL Listed, IEC | High |

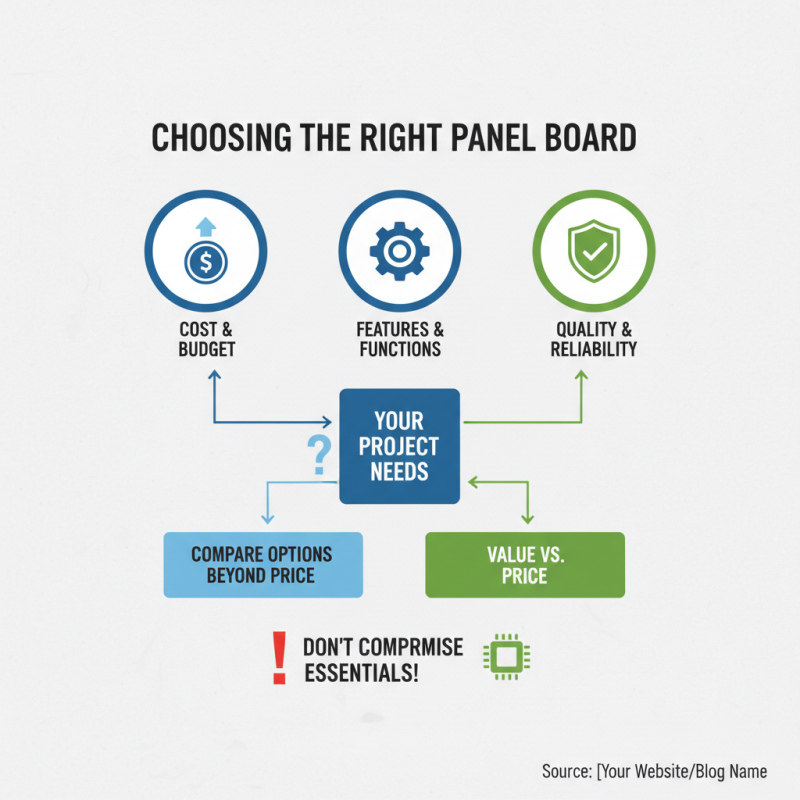

Choosing the right panel board can be a daunting task. Many brands offer a range of features and costs. It's crucial to compare options to find what fits your project best. Don’t just focus on the price. Sometimes cheaper models lack essential features that can impact your project’s success.

Start by evaluating the specifications you need. What size panel board do you require? How many circuits will you use? These factors affect both functionality and cost. Brands may vary in their features. Some provide advanced safety features, while others prioritize energy efficiency. Pay attention to warranty details as well. A longer warranty can save you money in the long run.

While high-end brands might seem appealing, they often come with a hefty price tag. Examine whether the additional features are necessary for your specific application. Sometimes a mid-range option is sufficient. Do not ignore user reviews. They can provide insight into common issues and maintenance costs. Reflect on your personal experience, and consider if you’ve prioritized cost over quality in the past. This could influence your decision-making process now.

When it comes to panel boards, installation and maintenance are crucial for their performance. Proper installation ensures longevity and efficiency. While it may seem simple, many overlook this step. Ensure all connections are tight to avoid issues later. Check the manufacturer's recommendations for proper placement.

Remember to regularly inspect your panel board. Dust and dirt can accumulate over time. This can lead to overheating. A simple cleaning routine can prevent this. Use a soft cloth to wipe down surfaces. This small task can make a big difference.

Keep an eye on the circuit breakers. Signs like flickering lights might indicate problems. If you notice tripped breakers frequently, reflect on your energy usage. You may need to redistribute loads across your panel board. Awareness is key to ensuring optimal performance.

This chart analyzes the efficiency of different panel boards based on their installation and maintenance frequency. The data reflects performance ratings derived from user feedback across various projects.